Component Sourcing Services for Hard-to-Find Components in Electronics Manufacturing

If you've ever found yourself scrambling to locate a critical component that seems to have vanished from the market, you're not alone. Electronics manufacturers everywhere face the growing challenge of sourcing hard-to-find components that are essential to keeping production lines running smoothly. Whether you're dealing with obsolete electronic components, specialty parts with limited availability, or components caught up in supply chain hiccups, finding reliable sourcing solutions has become more important than ever. Fortunately, professional component sourcing services offer the expertise, supplier connections, and quality verification processes you need to track down these elusive parts while ensuring they meet your standards for authenticity and performance.

Key Takeaways

- Professional sourcing services leverage extensive supplier networks to locate hard-to-find components that traditional channels cannot provide

- Authentication and quality verification processes protect manufacturers from counterfeit or substandard electronic parts

- Strategic inventory management helps manufacturers prepare for future component shortages and obsolescence issues

- Specialized sourcing expertise reduces procurement time and costs while maintaining production continuity

- Cross-reference databases and alternative component identification services offer viable substitutions for unavailable parts

- Supply chain risk mitigation strategies help manufacturers navigate market volatility and component availability challenges

Understanding Component Availability Challenges

The electronics manufacturing world has become quite the puzzle in recent years, with component availability issues popping up everywhere from consumer gadgets to heavy industrial equipment. When your usual distribution channels come up empty-handed for specialized or aging components, you're left to navigate a complex maze of alternative suppliers and creative procurement strategies.

You'll typically encounter hard-to-find electronic parts in several situations that each require their own approach:

- End-of-life components where manufacturers have stopped production, but there's still plenty of demand for replacement parts and ongoing repairs

- Low-volume specialty parts that serve very specific applications and might have limited production runs or require specialized manufacturing

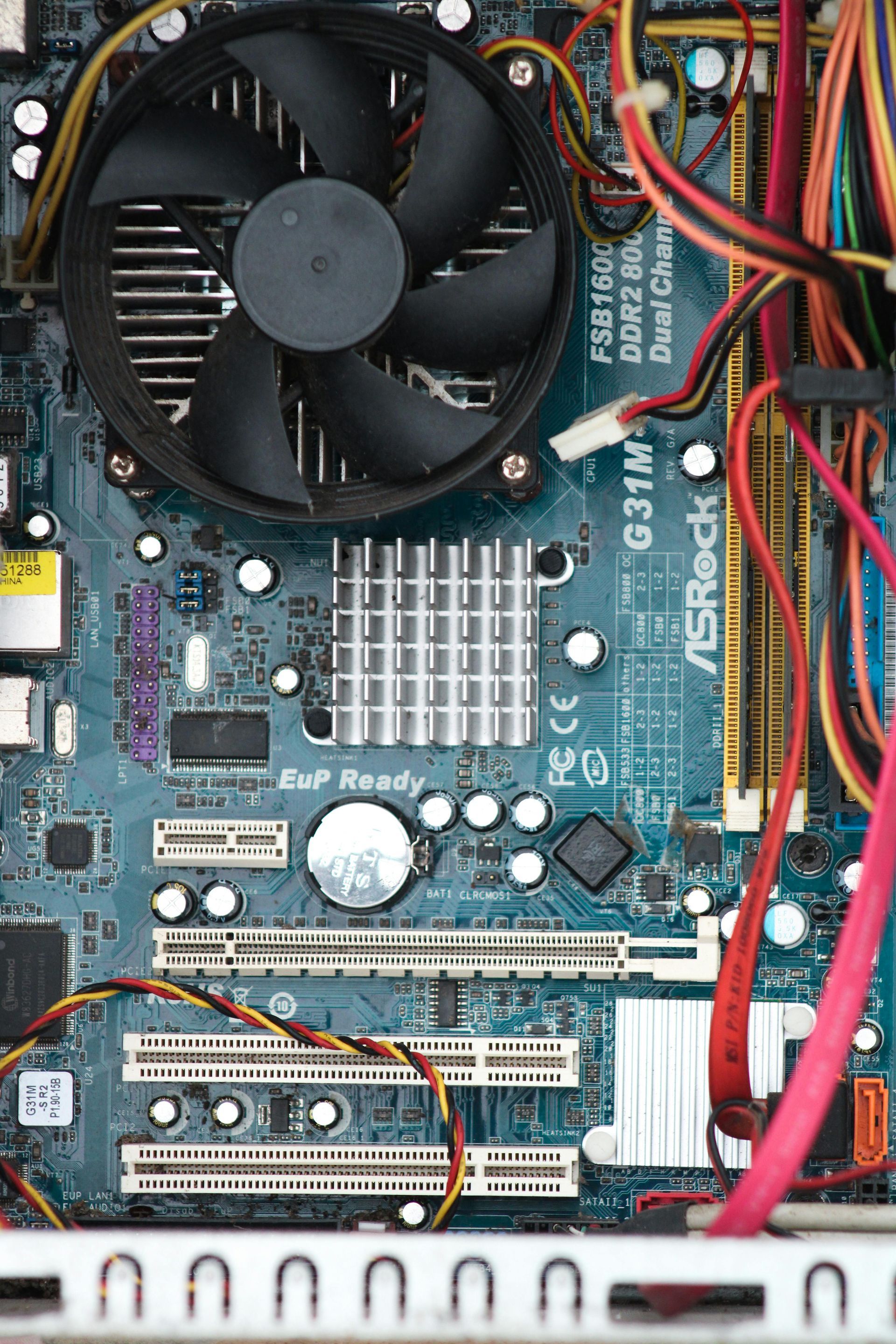

- Legacy components that are essential for keeping older equipment and systems running smoothly across various industries

- Supply-constrained parts where high demand or manufacturing hiccups have created temporary or extended shortages in the marketplace

These availability headaches can really throw a wrench in your production planning, cost management, and ability to keep customers happy. The key is finding that sweet spot between securing authentic, quality components and meeting your time-sensitive production needs without breaking the budget.

The Role of Professional Sourcing Services

Think of component sourcing specialists as your personal detectives in the electronics world. They bridge the gap between what you need and what's actually available out there, using their deep market knowledge and carefully cultivated supplier relationships to make the impossible possible.

These sourcing teams maintain impressive databases filled with authorized distributors, independent suppliers, and specialty vendors from around the globe. This extensive network gives you access to inventory that you'd never find through standard distribution channels or direct manufacturer sales.

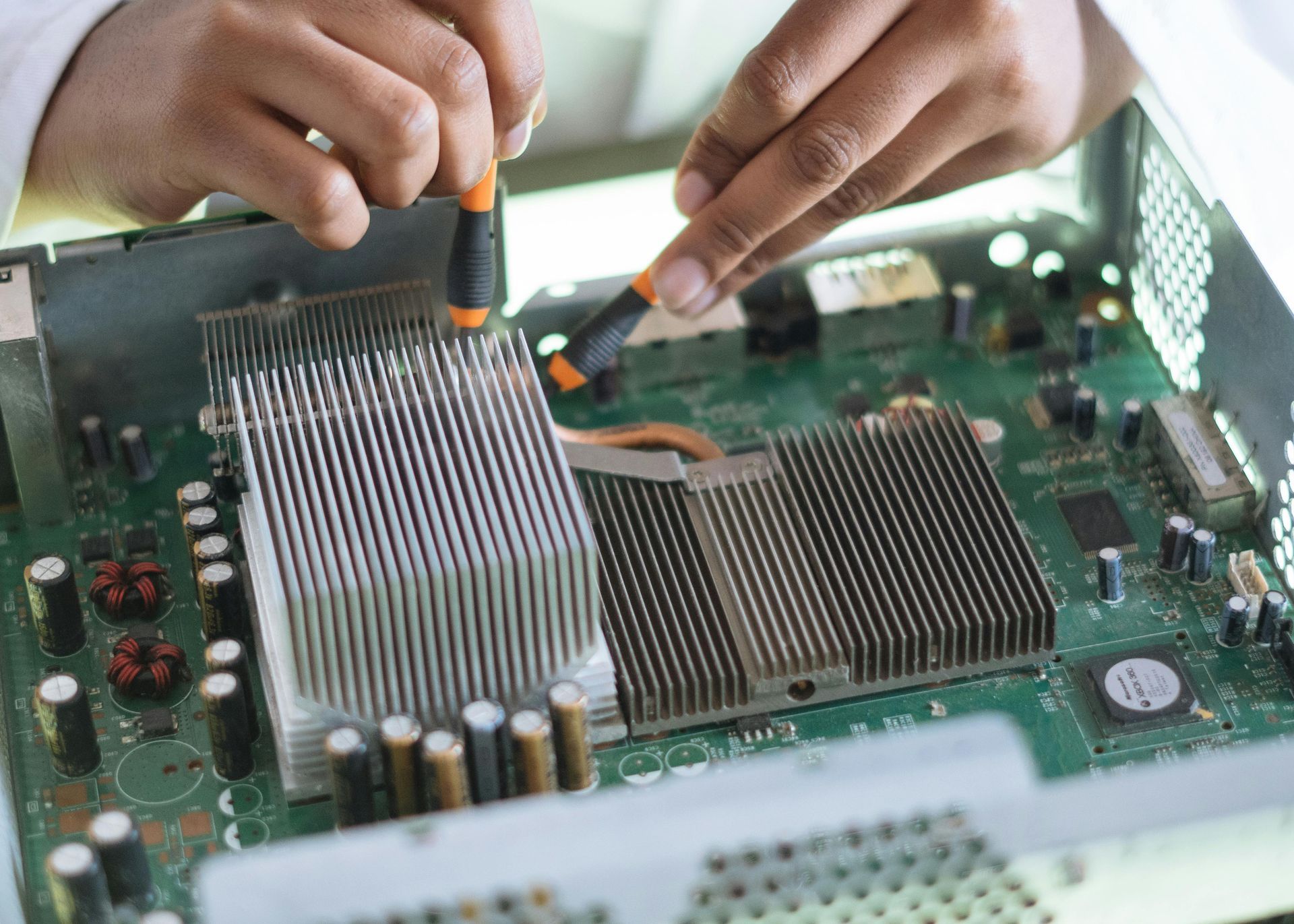

What really sets professional services apart is their authentication process. Let's face it: the market for hard-to-find components can be a bit like the Wild West, with counterfeit or questionable refurbished parts lurking around every corner. Experienced sourcing professionals have developed solid verification protocols that include thorough visual inspections, electrical testing, and documentation reviews to make sure you're getting the real deal.

Supplier Network Categories and Capabilities

| Supplier Type | Inventory Focus | Typical Lead Times | Quality Assurance |

|---|---|---|---|

| Authorized Distributors | Current production parts | 1-4 weeks | Full manufacturer backing |

| Independent Distributors | Excess and surplus inventory | 1-2 weeks | Vendor certification programs |

| Specialty Brokers | Obsolete and rare components | 2-8 weeks | Third-party testing available |

| Franchise Distributors | Broad line card coverage | 1-3 weeks | Manufacturer authorized |

| OEM Direct | End-of-life inventory | 4-12 weeks | Factory fresh stock |

Advanced Search and Identification Techniques

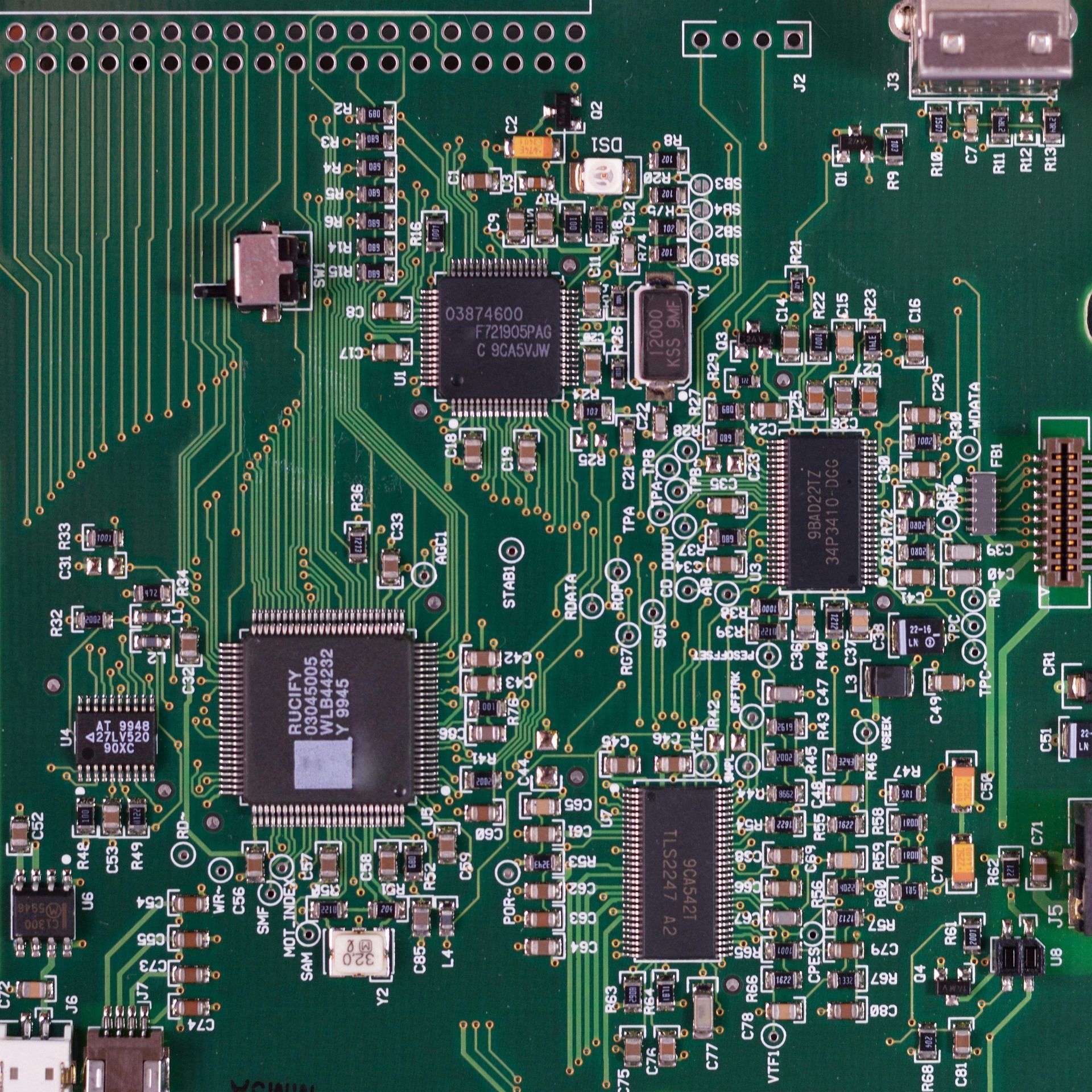

Today's component sourcing goes way beyond simply typing a part number into a search box and hoping for the best. Professional services use sophisticated search methods that can track down components through multiple databases, cross-reference tools, and detailed technical analysis.

Here's where things get interesting: part numbers can be tricky. Manufacturers sometimes rebrand components or update specifications over time, which can make searching for obsolete electronic components feel like detective work. The good news is that experienced sourcing teams know all these quirks and have systematic approaches to find what you need:

- Alternative part number searches that take into account manufacturer rebranding and specification changes that happen over time

- Parametric matching that focuses on electrical characteristics, package types, and functional requirements rather than getting hung up on specific part numbers

- Form-fit-function analysis to identify compatible substitutes that will do exactly what your original components did

- Date code and lot tracking to locate specific component versions when you need precision matching for legacy system compatibility

The best part about working with sourcing professionals is that they'll collaborate closely with your engineering team to validate alternative components and make sure everything plays nicely together. This teamwork helps you make smart decisions about component substitutions and any potential design tweaks you might need.

Quality Assurance and Authentication Processes

Nobody wants to deal with counterfeit parts or substandard components that could derail production or create liability headaches. That's why the component sourcing industry has developed robust quality assurance protocols that give you peace of mind about every part you receive.

The authentication process typically involves several verification stages that examine both the physical appearance and performance characteristics of your sourced components. Visual inspection helps catch obvious red flags like remarking, refurbishment signs, or physical damage that might indicate you're dealing with counterfeit or compromised parts.

Electrical testing is where the rubber meets the road: this validates that components actually perform according to their published specifications. This step becomes especially important for obsolete electronic components where age and storage conditions might have taken their toll on performance.

By verifying the accompanying documents, you can be assured that your components come with all the right certifications, test reports, and traceability information. This paperwork gives you the quality assurance data you need for your own production processes and regulatory compliance requirements.

Supply chain transparency lets you see the complete journey of your sourced components, from their original manufacture, through various distribution channels, right to your doorstep. This visibility helps you spot potential quality risks and ensures everyone stays accountable throughout the procurement process.

Cost Management and Procurement Strategies

Managing costs for hard-to-find components requires more strategy than just shopping around for the lowest price tag. Professional sourcing services bring valuable insights about market trends, pricing patterns, and timing considerations that can make a real difference in your total component costs.

Market intelligence helps you understand the supply and demand dynamics for specific components, so you can make better decisions about when and how much to buy. This information becomes especially valuable for obsolete electronic components where availability might be limited, and prices can swing dramatically.

When it comes to volume purchasing, bigger isn't always better. While bulk purchases often provide better unit costs, you need to carefully manage inventory to avoid ending up with obsolete parts gathering dust. Sourcing professionals help you strike the right balance through market analysis and demand forecasting.

Evaluating alternative components involves more than just comparing unit prices. You'll want to consider potential redesign costs and qualification expenses, too. A comprehensive cost assessment helps you make informed decisions about whether to substitute components or stick with sourcing the original parts.

Forward buying strategies involve purchasing components ahead of when you actually need them to secure availability and potentially lock in favorable pricing. These approaches require careful planning and market analysis to avoid excess inventory costs while ensuring you have components ready for future production runs.

Strategic Inventory Management Solutions

Getting ahead of component availability challenges before they impact your production schedule is always the smart move. This proactive approach involves working closely with sourcing specialists and your manufacturing teams to identify potential supply risks and develop backup plans.

Bill of materials analysis helps identify components that might be at high risk for obsolescence or supply chain problems, letting you develop contingency plans before shortages actually happen. This analysis looks at factors like manufacturer lifecycle status, market demand trends, and whether alternative components are readily available.

Buffer stock strategies provide insurance against unexpected component shortages while keeping inventory carrying costs reasonable. Professional sourcing services help determine the right stock levels based on how critical components are, typical lead times, and demand variability.

Obsolescence management programs keep an eye on component lifecycle status and give you early warnings about upcoming end-of-life announcements. This heads-up allows you to secure final inventory or identify alternative components before shortages develop.

Vendor-managed inventory arrangements can help maintain stock levels for critical components while reducing the burden of internal inventory management. These programs take advantage of supplier expertise and economies of scale to optimize inventory levels and costs.

Technology Integration and Digital Solutions

Modern component sourcing increasingly relies on smart technology platforms that bring together search capabilities, supplier networks, and inventory management tools. These digital solutions make everything more efficient and give you real-time visibility into component availability and pricing.

Database integration connects multiple supplier inventories and provides unified search capabilities across the global component market. This means you don't have to manually search through dozens of supplier websites, where everything's right at your fingertips in one comprehensive view.

Real-time inventory tracking lets you monitor component availability and receive alerts about potential shortages or price changes. This visibility supports proactive procurement decisions and helps you avoid those last-minute production scrambles.

Automated matching systems use artificial intelligence and machine learning to identify alternative components and suggest substitutions based on technical specifications and application requirements. These systems boost sourcing efficiency while maintaining technical accuracy.

Digital documentation management ensures that all component certifications, test reports, and quality documentation are properly organized and easily accessible whenever you need them for audits or compliance purposes.

Supply Chain Risk Mitigation

Component sourcing services play a vital role in helping you manage supply chain risks that could disrupt production or compromise product quality. These risk management strategies address both immediate sourcing challenges and long-term supply chain stability.

Supplier diversification reduces your dependence on single sources and provides alternative procurement options when primary suppliers face capacity constraints or quality issues. This diversification strategy requires ongoing supplier relationship management and performance monitoring to keep everything running smoothly.

Geographic risk assessment considers how regional disruptions, trade policies, and transportation challenges might impact component availability. This analysis helps you understand potential vulnerabilities and develop solid contingency plans for critical components.

Quality risk management involves comprehensive supplier qualification and ongoing performance monitoring to ensure consistent component quality. This process includes regular audits, performance metrics tracking, and corrective action protocols to address any issues quickly.

Counterfeit risk mitigation employs advanced authentication techniques and supply chain verification to protect against fake components that could compromise product performance or safety. These measures become increasingly important as component sourcing extends beyond traditional authorized channels.

Frequently Asked Questions

What makes a component "hard to find" in electronics manufacturing?

Components become hard to find when manufacturers discontinue production, supply chains face disruptions, or demand exceeds available supply. These situations commonly occur with obsolete electronic components, specialty low-volume parts, and legacy components for older equipment.

How do sourcing services verify the authenticity of hard-to-find electronic parts?

Professional services use multi-stage authentication, including visual inspection, electrical testing, documentation verification, and supply chain traceability. These processes help identify counterfeit or refurbished components that may not meet original specifications.

What are the typical lead times for sourcing obsolete electronic components?

Lead times vary significantly based on component rarity and supplier availability, ranging from one week for common surplus inventory to several months for extremely rare parts. Professional sourcing services provide realistic timelines based on market conditions and specific component requirements.

Can alternative components be substituted for hard-to-find components in existing designs?

Many hard-to-find components have suitable alternatives that provide equivalent functionality and performance characteristics. Sourcing specialists work with engineering teams to identify compatible substitutes and validate their suitability for specific applications.

How do manufacturers balance cost and quality when sourcing hard-to-find components?

Effective sourcing strategies consider the total cost of ownership, including procurement costs, quality risks, and potential production delays. Professional services help manufacturers evaluate these factors and make informed decisions about component sourcing and substitution options.

Final Thoughts

Working with professional component sourcing services can be a game-changer when you're dealing with the challenges of locating and procuring hard-to-find components in today's unpredictable supply chain environment. These specialized services bring together market expertise, supplier networks, and quality assurance processes to help you maintain production continuity while keeping costs and quality risks in check. By partnering with experienced sourcing professionals, you gain access to global component markets and benefit from proven strategies that have helped countless manufacturers successfully navigate component availability challenges.

Access our global network of verified suppliers for hard to find components. Reduce lead times, ensure authenticity, and keep production on schedule. Connect with our sourcing team now.

Reference:

https://en.wikipedia.org/wiki/Form,_fit_and_function