Obsolete Electronic Components: Reliable Solutions for Legacy Systems

When keeping legacy systems running, the search for obsolete electronic components that manufacturers stopped making years ago can feel like a treasure hunt. Whether you're managing medical equipment, industrial machinery, or telecommunications systems, finding discontinued electronic parts becomes a real challenge when something breaks down. The good news is that there are trusted obsolete electronics suppliers out there who know exactly how to help you keep your equipment running smoothly without breaking the bank on complete system replacements.

Key Takeaways

- Finding obsolete electronic components doesn't have to be a nightmare: some specialists know exactly where to look and how to get you what you need fast

- Working with experienced obsolete electronic components distributors saves you time and money while giving you peace of mind about getting genuine parts

- Planning ahead for component needs helps you avoid those panic moments when something fails, and you need parts yesterday

- When original components simply don't exist anymore, there are clever alternatives like custom manufacturing and reverse engineering that can save the day

- Getting authentic components verified by professionals protects your expensive equipment from counterfeit parts that could cause serious damage

- Building relationships with multiple obsolete electronics suppliers gives you backup options and access to different inventory networks when you really need them

Why Obsolete Components Become Such a Big Problem

Here's the thing about electronic components: they have a lifespan that's way shorter than the equipment they go into. While your industrial machine might be built to last 20 or 30 years, the little chips and circuits inside it were probably only manufactured for 5 to 10 years before the manufacturer moved on to something newer and better.

Manufacturers discontinue components for practical reasons. Maybe raw materials became too expensive, new regulations changed what they could use, or there just wasn't enough demand to keep production running. Sometimes they develop newer technology that makes old components look outdated, so they focus resources on the latest developments instead.

The real challenge hits when you're running equipment that absolutely cannot go down. Think about hospitals with life-saving medical devices, factories with production lines that cost thousands per hour when stopped, or telecommunications companies keeping entire cities connected. Industries like aerospace and defense face even tougher challenges because their systems need to operate for decades without major overhauls.

The financial impact goes beyond just the cost of the component itself. When a system goes down, you're looking at lost productivity, emergency service calls, expedited shipping fees, and sometimes safety risks. Smart companies have learned that investing in good obsolete component sourcing upfront saves them from these expensive emergencies down the road.

The Most Common Hard-to-Find Components You'll Encounter

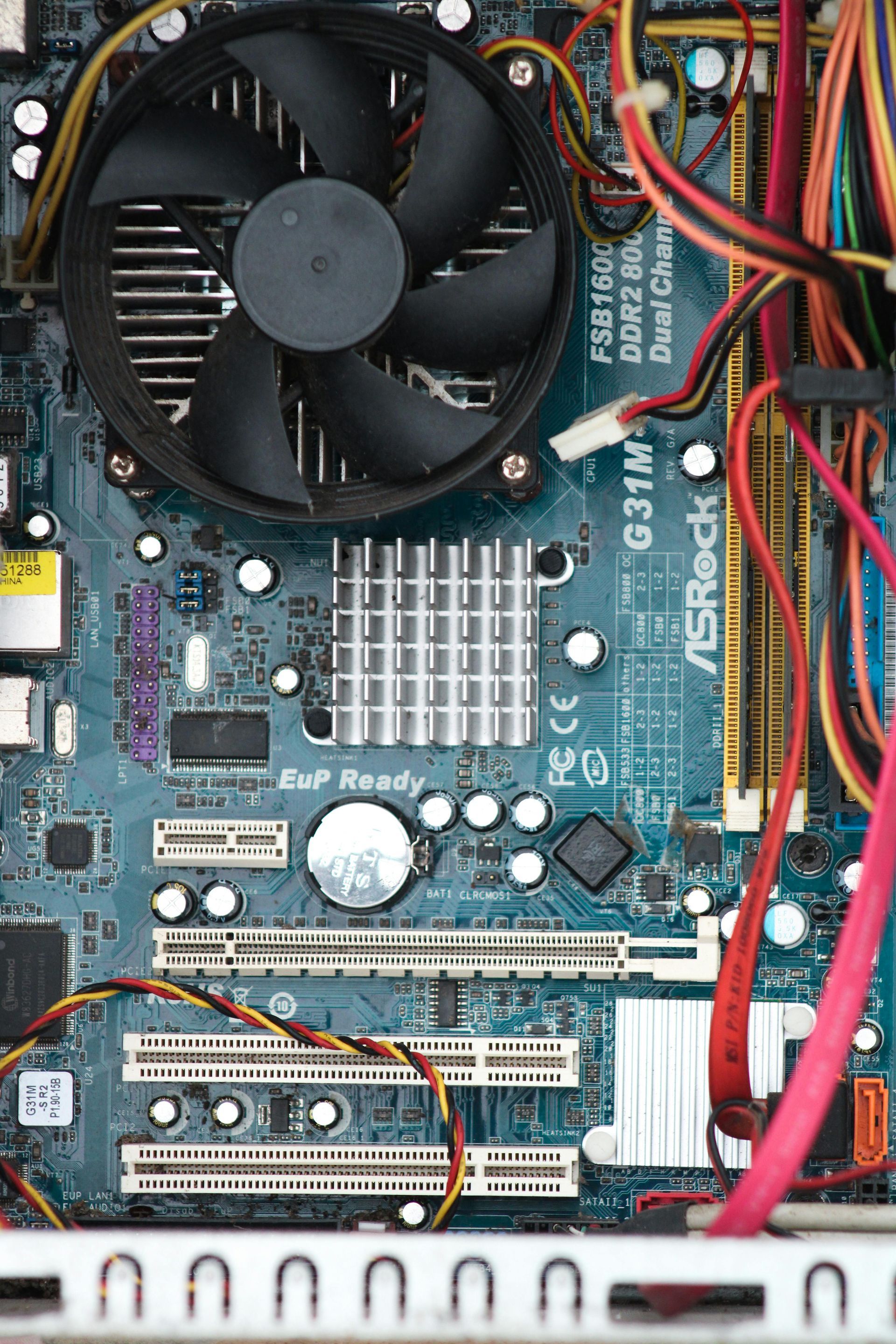

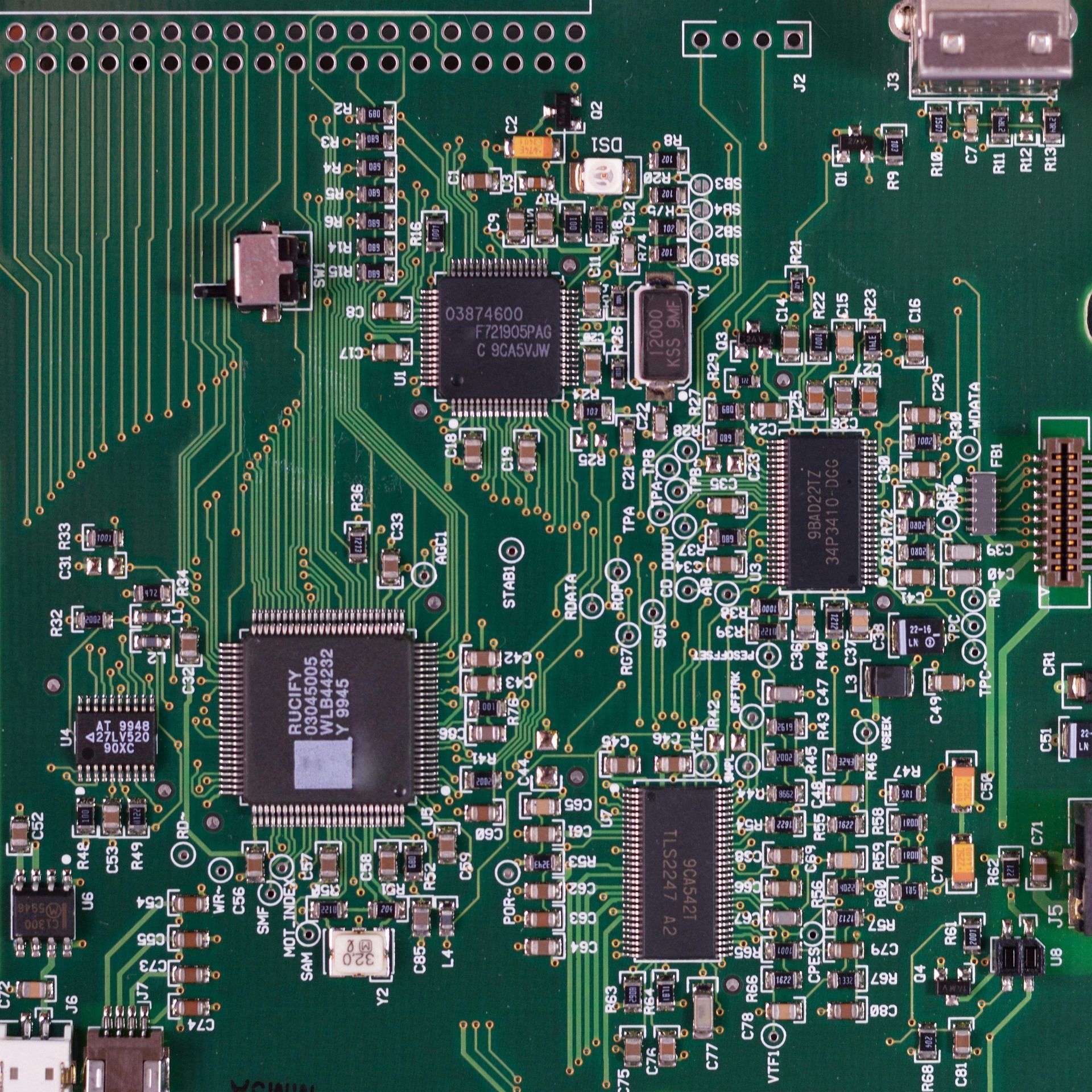

If you've been hunting for obsolete electronic components, you've probably noticed that some types are much harder to find than others. Integrated circuits top the list because these complex components are expensive to manufacture and require specialized facilities. When a chip company decides to stop making a particular processor or memory module, they're not likely to fire up that production line again just because you need a few dozen pieces.

| Component Category | Common Applications | Why They're Hard to Find |

|---|---|---|

| Integrated Circuits | Control systems, processors, memory modules | Complex manufacturing, rapid technology changes |

| Discrete Components | Power supplies, amplifiers, switching circuits | Package style changes, tighter specifications |

| Passive Components | Capacitors, resistors, inductors | Environmental regulations, size optimization |

| Connectors & Cables | Interface connections, data transmission | Standard evolution, mechanical improvements |

Discrete components like transistors and voltage regulators can be just as frustrating to track down. The tricky part is that while a newer transistor might seem like it should work as a replacement, the devil is in the details. Maybe the old one had a slightly different voltage rating, or the package size is just a millimeter off. In precision applications, these small differences can be deal-breakers.

Smart Strategies for Finding Obsolete Electronics

Finding obsolete electronic components isn't as hopeless as it might seem: you just need to know where to look and how to approach the search. The key is developing a strategy that gives you several different avenues to explore.

Your first stop should be specialized obsolete electronic components suppliers. These folks have made it their business to track down and stockpile components that are no longer in regular production. Think of them as the treasure hunters of the electronics world: they know where to look, have connections you don't, and understand what you're going through when you're desperately searching for a part.

Authorized distributors are valuable too, especially if you can catch them before a component goes completely obsolete. Many distributors will do a 'last time buy' when they know a manufacturer is discontinuing something. Independent distributors who focus specifically on obsolete electronics often have the most interesting inventory, with warehouses full of parts from companies that don't even exist anymore. What makes them really valuable is that they usually offer more than just parts:

- Component cross-referencing services to help you find suitable alternatives when exact matches aren't available

- Testing and verification to make sure old components still work properly after sitting on a shelf for years

- Flexible purchasing arrangements like consignment programs, where they keep inventory at your facility

- Technical support to help you figure out if a similar component might work as a substitute

Don't overlook surplus equipment dealers and companies that specialize in asset recovery. When factories close down or upgrade their equipment, these dealers often end up with whole assemblies containing multiple components that might be exactly what you need. Online marketplaces can be goldmines, but they're also minefields. Stick to sellers with good reputations and always factor in the cost of verification testing.

Making Sure You Get the Real Deal: Quality and Authentication

The world of obsolete electronic components is unfortunately full of counterfeit parts that can cause serious damage to your equipment. When you're dealing with components that are no longer in regular production, the risk of encountering fake parts goes way up because there's less oversight and more opportunity for bad actors to slip counterfeits into the supply chain.

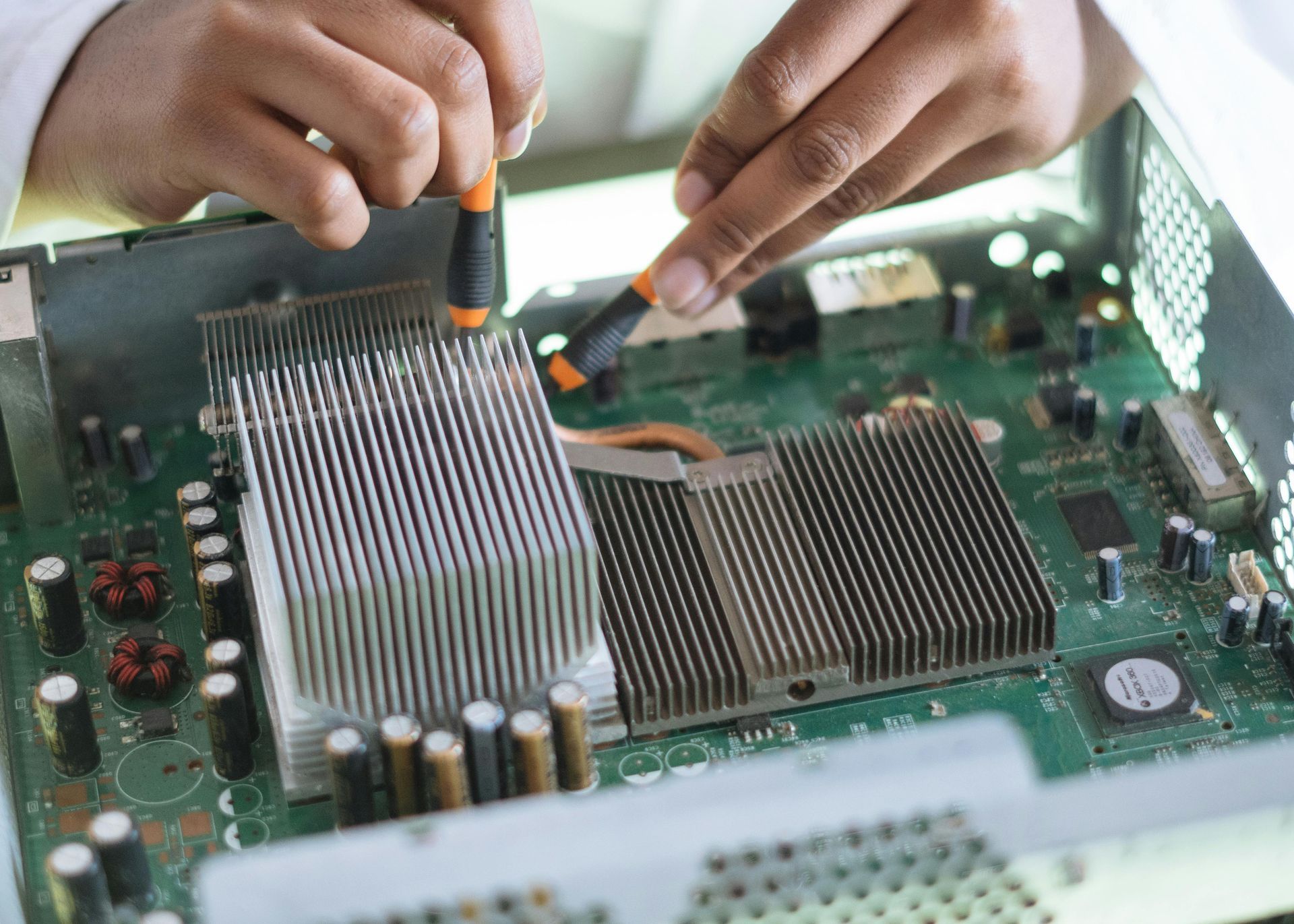

Reputable obsolete electronic components distributors take authentication very seriously. They know their reputation depends on providing genuine parts, so they've invested in testing equipment and processes that can catch most counterfeits. Visual inspection is usually the first line of defense: experienced technicians can often spot problems just by looking at components under magnification.

Electrical testing takes things further by actually checking whether components behave the way they should. For critical applications, some suppliers use X-ray analysis to look inside components without damaging them, or even decapsulation, where they carefully remove packaging to examine the actual silicon die inside.

Documentation is another crucial piece of the puzzle. Legitimate components should come with proper paperwork showing their chain of custody, test results, and certifications. When evaluating a potential supplier, ask about their authentication processes. A reputable supplier should be happy to explain how they verify components and what testing they do. If they're evasive about quality control, that's a sign to look elsewhere.

When Original Parts Just Don't Exist: Creative Alternatives

Sometimes you hit a dead end; the component you need simply doesn't exist anywhere, at any price. When you reach this point, it's time to get creative and look at alternatives that can keep your system running.

Form-fit-function replacements are often your best bet when original components are impossible to find. The idea here is to find or create a component that has the same physical dimensions, electrical connections, and performance characteristics as the original, even if it's built using newer technology. This works especially well for things like power supplies, where technology has improved but basic requirements haven't changed much.

Reverse engineering is another option that's becoming more accessible. You take your broken component to a company that specializes in figuring out how electronic parts work. They'll analyze the component, create detailed specifications, and then work with manufacturers to produce new components that do exactly the same job.

Custom manufacturing takes reverse engineering one step further by actually producing new components. This used to be something only large companies could afford, but improvements in manufacturing technology have made small-batch production much more economical. Modern techniques like 3D printing and flexible circuit board production have opened up new possibilities for creating replacement components.

Building Your Network: Creating Relationships That Work

One of the smartest things you can do for your long-term obsolete component sourcing is to build relationships with multiple suppliers before you actually need them. It's like having a good mechanic: you want to find them and get to know them before your car breaks down on the highway.

Different obsolete electronic components suppliers often specialize in different areas. One might have connections for military and aerospace components, while another focuses on industrial automation parts. By building relationships with several different suppliers, you're much more likely to find what you need when you need it.

Don't wait until you have an emergency to start these relationships. Reach out to suppliers when things are calm and you have time to properly evaluate their capabilities. Regular communication is key: even when you don't have immediate needs, check in occasionally with your suppliers. Let them know about upcoming projects or potential component needs.

Consider setting up formal agreements with your best suppliers. These might include consignment arrangements or service level agreements that guarantee response times for urgent requests. Remember that good supplier relationships work both ways: be a good customer by paying bills promptly, providing clear specifications, and giving feedback about components you receive.

Frequently Asked Questions

How can I tell if an obsolete electronic component is genuine and not counterfeit?

Work with reputable suppliers who can provide detailed documentation and test certificates for their components. Look for suppliers who use professional authentication methods like visual inspection, electrical testing, and verification of manufacturer markings and date codes.

What details should I provide when I'm searching for hard-to-find components?

Give complete part numbers, manufacturer information, and specific application requirements, including electrical specs and package types. Photos of the existing components and details about how they're used help suppliers identify suitable alternatives when exact matches aren't available.

How long does it typically take to get obsolete components delivered?

Delivery times depend heavily on component availability and rarity. Components that suppliers have in stock might ship within a few days, while rare components that require hunting through global networks can take several weeks or even months to locate.

Can I trust refurbished components for important applications?

Properly refurbished components from qualified suppliers with good testing processes can work well for many applications. However, for really critical systems where failure could cause safety issues or major financial losses, you might want to stick with new old stock or consider custom manufacturing options.

What are my options when exact replacement components don't exist anywhere?

Consider form-fit-function alternatives that do the same job with different technology, reverse engineering solutions that recreate the component specifications, or custom manufacturing for new components. Experienced suppliers can help you evaluate these options and provide technical support for integration challenges.

Final Thoughts

Dealing with obsolete electronic components doesn't have to be the headache it once was. With the right approach, finding trustworthy obsolete electronics suppliers, building good relationships before you need them, and having backup plans ready, you can keep your legacy systems running smoothly for years to come. The key is being proactive rather than reactive, and remembering that there are experienced professionals out there who've made it their business to help solve exactly the problems you're facing. When you work with the right partners and plan ahead, those hard-to-find components become much easier to find.

Struggling to find obsolete electronic components for your legacy systems? Contact our experienced team today to discuss your specific component needs and discover reliable sourcing solutions that keep your equipment running smoothly

Reference:

https://www.allpcb.com/allelectrohub/the-ultimate-guide-to-x-ray-inspection-for-electronic-components-from-diodes-to-ics