Box Build Assembly Services: Turnkey Electronics Manufacturing

When you need more than just PCB soldering, our Box Build Assembly Services provide a complete, turnkey electronics manufacturing solution. We integrate your printed circuit boards, wiring harnesses, enclosures, and accessories into fully assembled, tested, and ready-to-ship products. Whether you’re launching a new industrial automation device, scaling a telecom solution, or prototyping a medical instrument, our expert team and AI-driven processes ensure your next-gen electronics hit the market faster and at lower cost.

Why Partner with Us for Box Build Assembly?

Turnkey Electronics Manufacturing

Eliminate multi-vendor headaches by consolidating sourcing, assembly, testing, and packaging under one roof. Our turnkey approach streamlines communication and reduces lead times.

AI-Driven Workflow Optimization

Leveraging machine-learning algorithms, we predict bottlenecks, optimize labor allocation, and minimize material waste—delivering cost savings of up to 20% versus manual planning.

Scalability from Prototype to High Volume

Whether you need a handful of prototypes or thousands of units per month, our flexible production lines and strategic vendor partnerships adapt to your growth trajectory.

Industry Compliance & Standards

We adhere to IPC-A-610, ISO 9001:2015, and UL 508A standards, ensuring every assembly meets rigorous safety and performance requirements.

Industries We Serve

- Medical Devices: Rugged, sterilizable enclosures and Class II/III device testing.

- Industrial Automation: Vibration-resistant builds for PLCs and motor controllers.

- Telecommunications: High-speed RF modules and network-ready boxes.

- Aerospace & Defense: Mil-spec components, conformal coating, and secure chain of custody.

- Consumer Electronics: Sleek, retail-ready packaging and UL certification support.

Our Box Build Assembly Process

1. Consultation & Design Review

We start with a deep dive into your mechanical drawings, schematics, and test requirements—identifying cost-saving opportunities and potential design improvements.

2. Prototype Run & DFx Feedback

Early prototypes help us validate manufacturability. We provide Design for Excellence (DFx) recommendations to optimize yield and reliability.

3. Component Sourcing & Kitting

Our supply-chain team sources qualified components, manages EOL risks, and delivers kitted materials to our production floor.

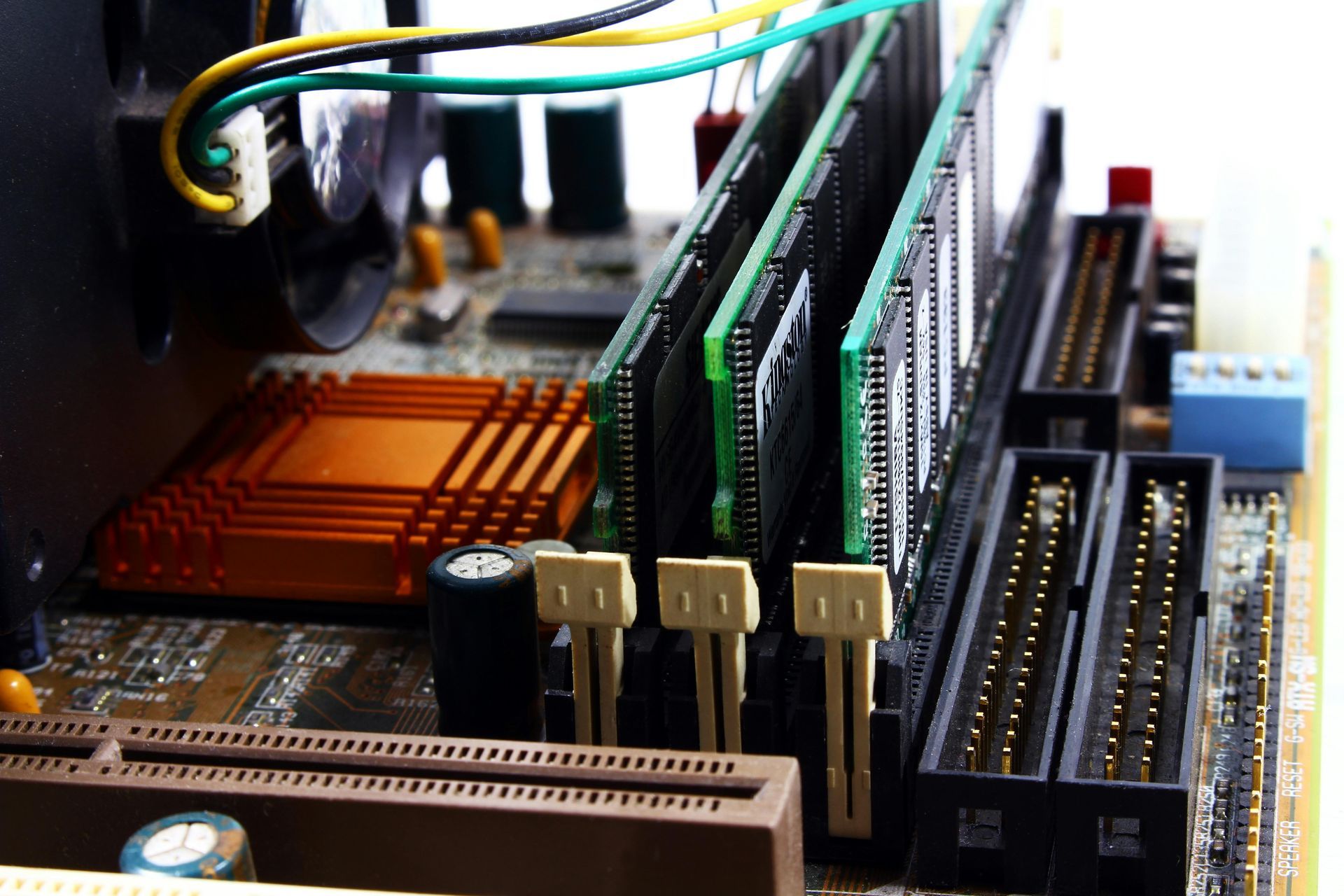

4. Assembly & In-Line Inspection

Automated pick-and-place, wave solder, or hand-assembly stations are complemented by in-line vision-system checks to catch defects early.

5. Functional & Environmental Testing

Every unit undergoes full functional testing, optional environmental stress screening (ESS), and final QA audits.

6. Final Packaging & Logistics

Completed units are serialized, packaged, and shipped with your choice of transport and customs documentation.

Frequently Asked Questions

What is box build assembly and how does it differ from PCB assembly?

Box build assembly is a turnkey electronics manufacturing process where we integrate PCBs, wiring, enclosures, and accessories into a finished product ready to ship. Unlike simple PCB assembly (which mounts components onto boards), box build includes mechanical assembly, wiring harnesses, tests, and packaging.

Why should I choose EPSEMS for box build assembly?

EPSEMS offers a complete turnkey solution that cuts out coordination across multiple vendors. We handle enclosure integration, cable harnessing, serialization, functional testing, and packaging—all under one roof. This helps you save time, reduce costs, and simplify logistics.

What kinds of testing do you perform during box build assembly?

We run in-line inspections, power integrity checks, signal validation, burn-in testing, and optional environmental screening. Every unit gets a pass/fail report logged in our digital traceability system. This ensures reliability and compliance.

Can you handle small prototype runs as well as large production volumes?

Yes. Our production lines are flexible. We support prototype builds to test design concepts, and we scale up to high-volume manufacturing without losing quality or consistency.

What industries or products are suitable for your box build services?

We serve industries like medical devices, industrial automation, telecommunications, aerospace & defense, and consumer electronics. Any device needing enclosure integration, wiring, testing, and final packaging can benefit from our box build service.

Ready to Accelerate Your Time to Market?

Don’t let production assembly become your bottleneck. Partner with us for seamless Box Build Assembly Services that deliver precision, reliability, and full supply-chain transparency.

📞 Contact Us Today for a custom quote and start turning your designs into field-ready products tomorrow.