What Goes into Custom Cable Assembly: An Insider's Breakdown

If you've ever wondered what really goes into creating those custom cable assemblies that power everything from medical devices to industrial machinery, you're in for an interesting journey. The world of custom cable assembly manufacturing might seem straightforward from the outside, but there's actually a fascinating blend of engineering precision, material science, and quality craftsmanship that goes into every single assembly. Whether you're working on a cutting-edge automotive project or developing the next breakthrough medical device, understanding what happens behind the scenes can help you make better decisions for your specific needs and ensure you get exactly what your application requires.

Key Takeaways

- Material selection and wire gauge specifications form the foundation of reliable custom cable assembly performance

- Quality control measures, including continuity testing and insulation resistance checks, ensure assemblies meet industry standards

- Environmental considerations like temperature and chemical exposure directly influence connector types and shielding requirements

- Documentation requirements vary by industry, with medical and aerospace needing comprehensive validation records

- Manufacturing scalability depends on design complexity, with simpler assemblies supporting higher volumes

- Cost optimization balances material quality, labor requirements, and testing protocols while maintaining performance

Understanding Custom Cable Assembly Requirements

Think of starting a custom cable assembly project like planning a road trip: you need to know where you're going, what conditions you'll encounter, and what vehicle will get you there safely. Every successful project begins with a thorough requirements analysis where professional cable and harness manufacturers work closely with you to understand your specific needs.

Key electrical requirements include:

- Voltage ratings and current capacity determine the basic wire selection and insulation requirements

- Signal integrity requirements affect whether you need controlled impedance cables with precise conductor spacing

- Power distribution needs might require heavy-gauge conductors with robust insulation systems

Environmental factors can make or break your assembly's performance over time. Temperature extremes, chemical exposure, moisture levels, and mechanical stress all influence material selection and assembly techniques. Medical device applications often require biocompatible materials and sterilization compatibility, while industrial environments may demand chemical-resistant jackets and enhanced mechanical protection.

Physical constraints often present the most interesting design challenges. Smart cable assembly manufacturers consider installation requirements, maintenance access, and potential interference with other system components right from the start.

Wire and Cable Material Selection Process

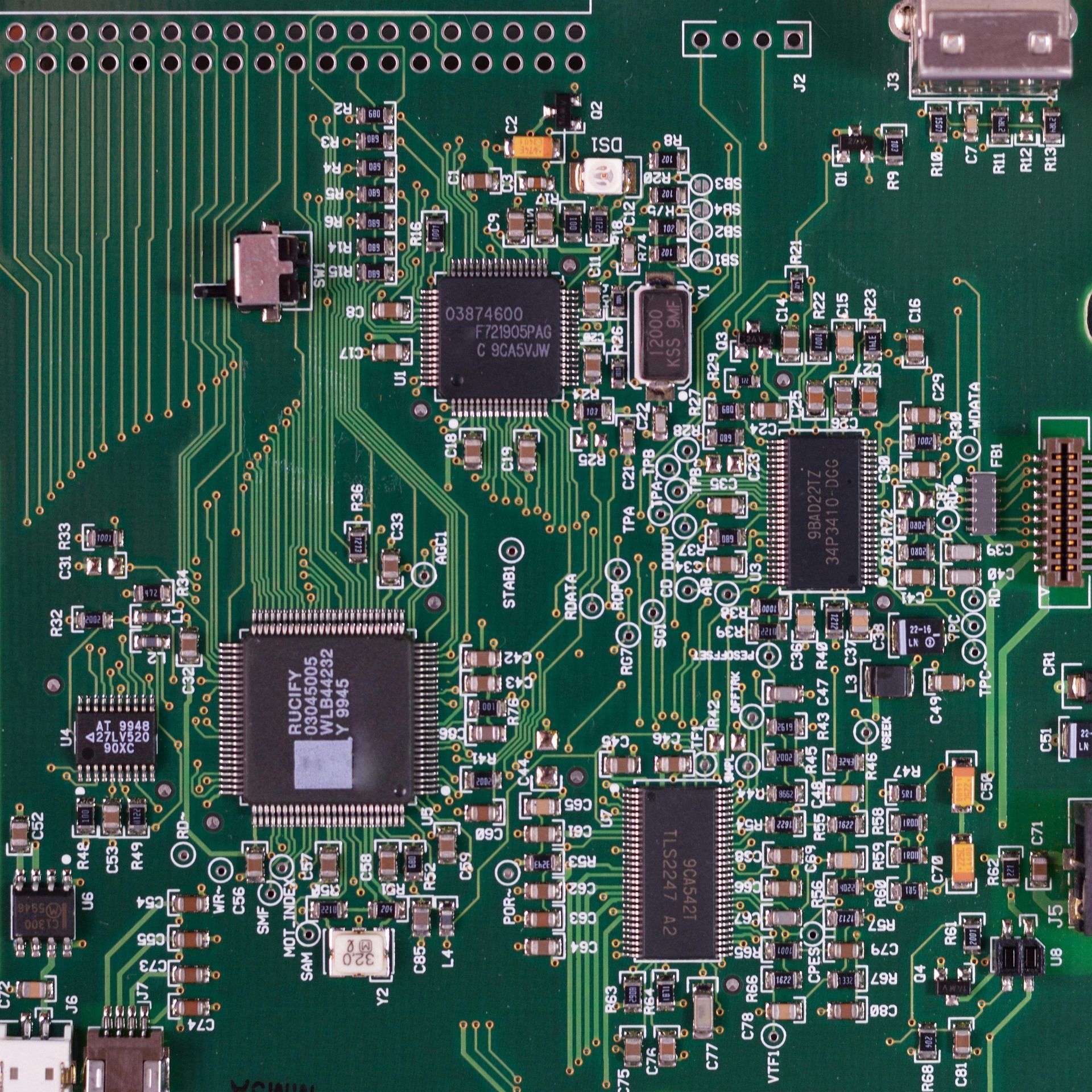

Choosing the right wire for your custom cable assembly is a bit like selecting ingredients for a dish: each component needs to complement the others while serving its specific purpose. Wire selection represents one of the most critical decisions in the entire manufacturing process, and getting it wrong can lead to performance issues or premature failure.

Key wire selection considerations include:

- Conductor material, typically copper or copper alloy, must provide adequate current-carrying capacity while maintaining flexibility

- Stranded conductors offer superior flexibility for applications requiring frequent movement or vibration resistance

- Solid conductors provide better high-frequency performance in stationary installations where flexibility isn't critical

- Wire gauge selection requires careful consideration of current requirements, voltage drop limitations, and physical space constraints

Undersized conductors can cause dangerous overheating and voltage drops that affect system performance, while oversized conductors waste space and increase costs unnecessarily. The choice between stranded and solid often depends on whether your assembly will experience regular flexing or remain in a fixed position throughout its service life.

Insulation materials deserve special attention because they're often the first line of defense against environmental challenges. Common insulation options include:

- Standard PVC insulation works well for general-purpose applications with moderate temperature and chemical exposure

- PTFE provides superior temperature resistance and chemical compatibility for demanding industrial applications

- Polyurethane offers excellent flexibility and abrasion resistance for dynamic applications

- Biocompatible materials like specialized TPE compounds resist bodily fluids and cleaning agents for medical applications

The insulation thickness also matters significantly: thicker insulation provides better protection against environmental challenges but increases overall assembly size and weight, which can impact routing and installation requirements.

| Wire Type | Temperature Range | Primary Applications | Key Benefits |

|---|---|---|---|

| PVC Insulated | -40°C to +105°C | General industrial, commercial electronics | Cost-effective, versatile |

| PTFE Insulated | -65°C to +200°C | Aerospace, high-temperature industrial | Chemical resistance, high-temp stability |

| Polyurethane | -40°C to +80°C | Medical devices, robotics | Flexibility, biocompatibility |

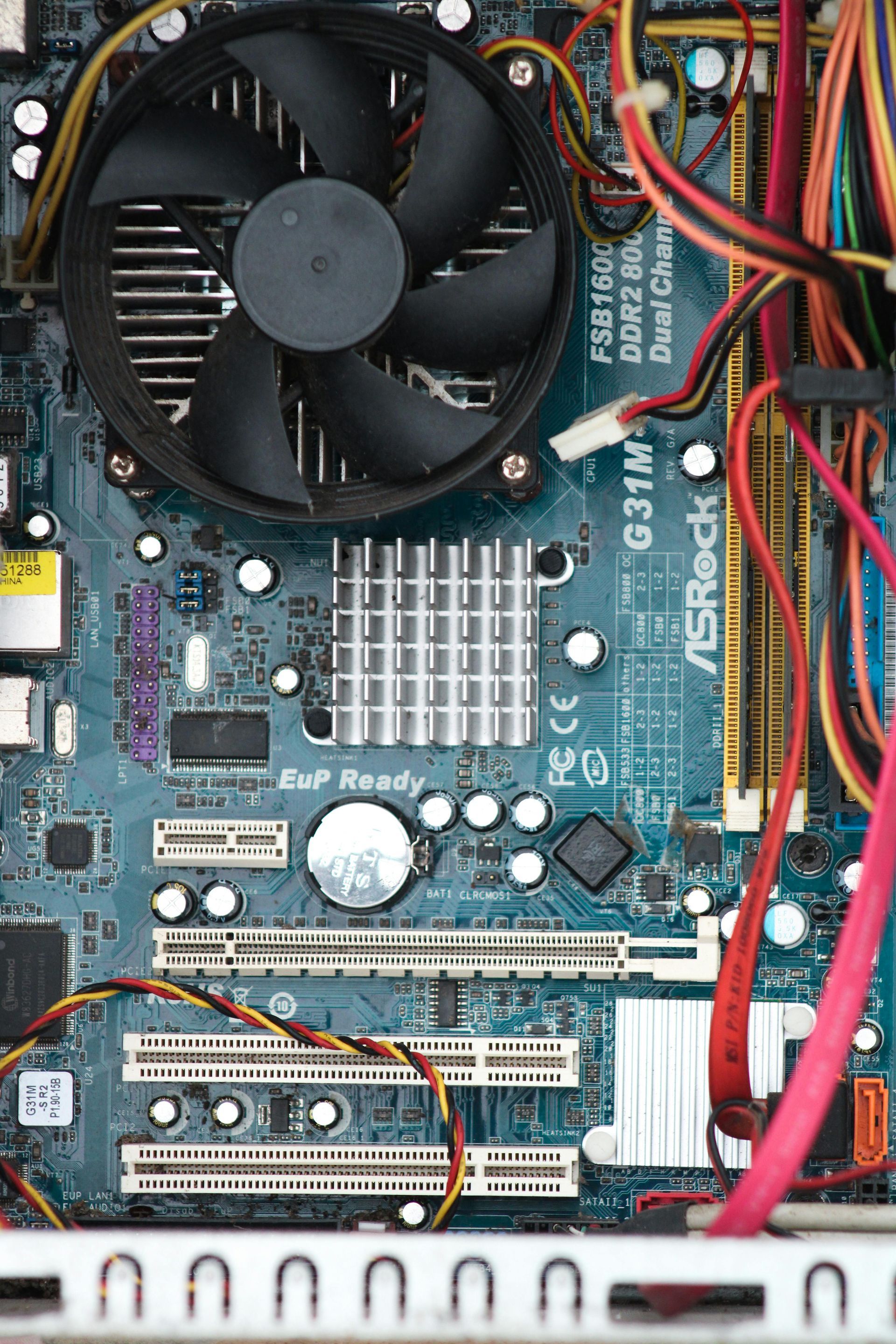

Shielding requirements deserve careful consideration, especially in today's electromagnetic environment, where interference can come from countless sources. The choice between different shielding options depends on your specific EMI challenges and performance requirements.

Popular shielding options include:

- Braided shields provide excellent coverage and flexibility, making them ideal for cables that need to move or bend frequently

- Foil shields offer cost-effective protection for less demanding applications where maximum flexibility isn't required

- Combination shields using both braided and foil layers deliver maximum protection for sensitive signal transmission

- Spiral wrap shields work well for applications where some flexibility is needed but full braided coverage isn't necessary

Manufacturing Process and Assembly Techniques

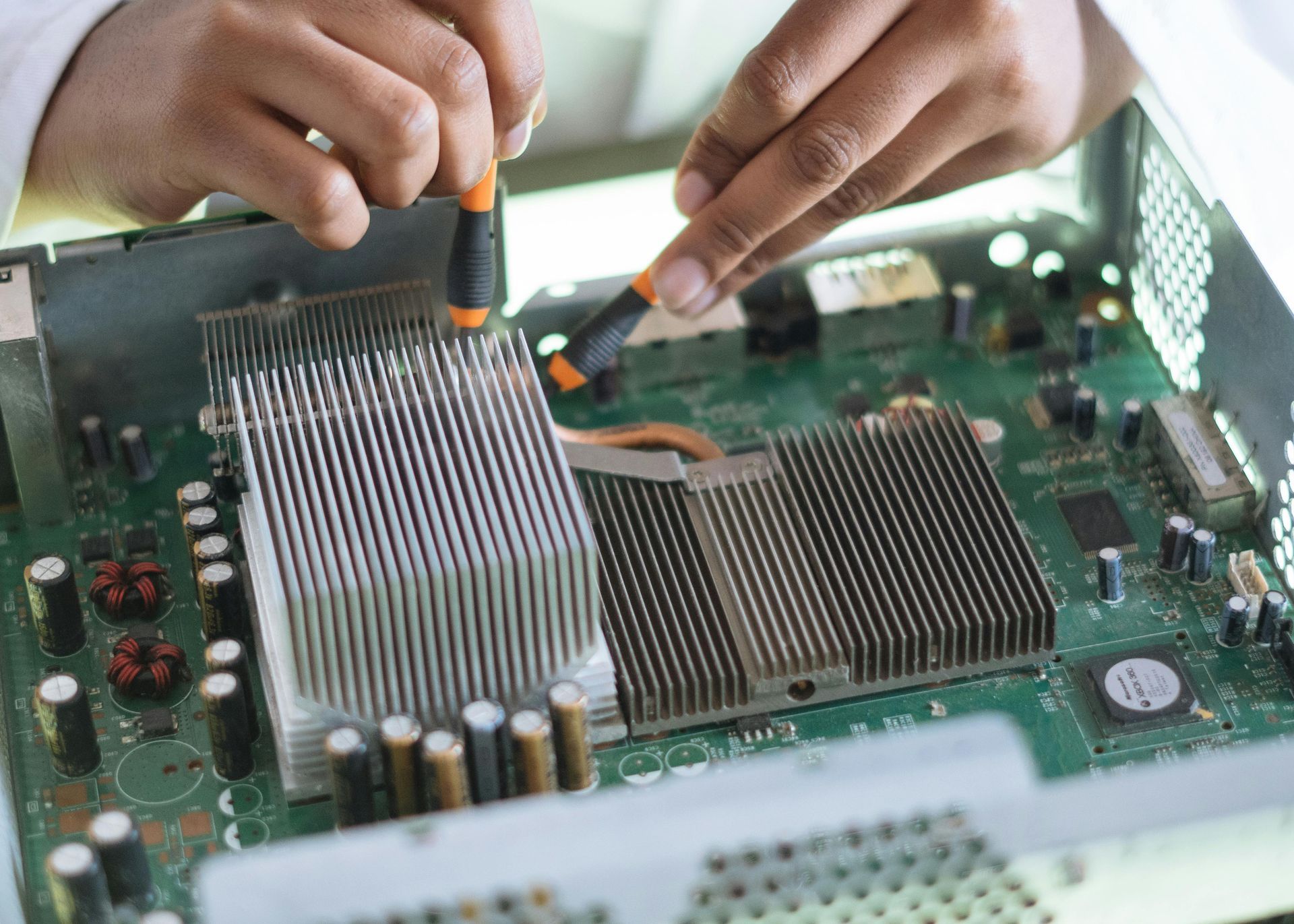

Walking through a professional cable assembly facility is like watching a carefully choreographed dance where precision meets efficiency. The manufacturing process follows structured procedures designed to ensure consistency, reliability, and quality in every single assembly. Modern facilities combine automated equipment with skilled technicians to achieve levels of precision that would be impossible through manual processes alone.

The process begins with wire preparation using automated equipment that maintains precise tolerances:

- Wire cutting operations maintain precise tolerances, often to within fractions of an inch

- Stripping operations require careful control to remove insulation without damaging conductors

- Quality checks at this stage prevent defective preparation from affecting downstream processes

Termination techniques vary significantly based on connector types and application requirements. Common methods include crimping operations that require precise tool selection and force application, soldering processes with controlled temperatures, and automated crimping systems that monitor force application and provide real-time quality feedback. Each termination method has its advantages: crimping offers speed and consistency for high-volume production, while soldering provides excellent electrical performance for critical applications.

Molded cable assemblies represent a specialized manufacturing area requiring injection molding equipment and precise temperature control. The molding process encapsulates connection points within protective housings, providing strain relief and environmental sealing that's particularly valuable for waterproof connections or enhanced mechanical protection. This process requires specialized tooling and careful material selection to ensure proper adhesion and long-term reliability.

Quality Control and Testing Protocols

Quality control in custom cable assembly manufacturing is like having a thorough medical checkup: you want to catch any potential issues before they become serious problems. The best manufacturers implement quality measures at every step of the process, starting with incoming material inspection, where they verify specifications before materials enter production.

Incoming material inspection includes:

- Wire specifications verified to ensure they match ordered requirements for gauge, insulation type, and performance ratings

- Conductor resistance measurements confirm proper wire gauge and material composition

- Connector quality checks verify dimensional accuracy and contact plating integrity

Essential electrical tests form the backbone of quality assurance, providing objective verification that assemblies meet specified performance standards:

- Continuity testing confirms proper connections between designated points while identifying opens or shorts

- Insulation resistance measurement verifies adequate separation between conductors under specified voltage conditions

- High-voltage (hi-pot) testing applies elevated voltages to detect insulation weaknesses that could cause field failures

Visual inspection protocols examine crimping quality, solder joint appearance, and overall assembly workmanship using magnification equipment. Environmental testing validates performance under real-world operating conditions, including temperature cycling, vibration exposure, and humidity testing to ensure assemblies maintain electrical performance and mechanical integrity throughout their service life.

Industry Standards and Compliance Requirements

Navigating industry standards for custom wire harness manufacturing can feel like learning a new language, but it's essential for ensuring your assemblies meet regulatory requirements. The good news is that experienced manufacturers understand these standards inside and out, so you don't have to become an expert yourself.

Key standards include UL (Underwriters Laboratories) for electrical product safety, military specifications (MIL-SPEC) for defense applications, ISO 13485 for medical device quality management, and ISO/TS 16949 for automotive quality management. Electromagnetic compatibility (EMC) testing ensures assemblies don't create interference or suffer from external electromagnetic fields.

Documentation requirements vary dramatically between industries. Medical and aerospace applications typically require comprehensive validation records, material certifications, and detailed testing reports that provide complete traceability. Commercial applications may require only basic compliance documentation, while consumer products often need safety certifications.

The certification process involves third-party testing and validation against applicable standards. Working with experienced cable and harness manufacturers familiar with relevant standards significantly streamlines certification processes and reduces development timelines.

Cost Optimization Strategies

Let's be honest: cost is almost always a major consideration in custom cable assembly projects, but it shouldn't be the only factor driving your decisions. Effective cost management requires finding the right balance between performance requirements and budget constraints. The goal isn't necessarily to build the cheapest assembly possible, but rather to get the best value for your specific application needs.

Smart material selection strategies include:

- Avoiding over-specification of materials that provide unnecessary performance characteristics at premium prices

- Selecting standard grades that meet requirements without paying for specialized compounds

- Considering material availability to avoid long lead times and price premiums for rare materials

Design optimization focuses on simplifying assembly processes and reducing labor requirements. Effective approaches include standardizing connector types across multiple assemblies, minimizing the number of different wire types and colors, and considering designs that can take advantage of automated processes rather than requiring extensive hand assembly.

Volume considerations affect pricing structures significantly. Higher quantities enable automated manufacturing processes and bulk material purchasing, which can dramatically reduce per-unit costs. However, minimum order quantities may make small prototype runs expensive, so it's important to plan accordingly. Many manufacturers offer prototype pricing that bridges the gap between development and production volumes.

Testing requirements should be tailored to actual application needs rather than following generic protocols. While comprehensive testing ensures reliability, excessive testing can significantly increase costs. Work with your manufacturer to identify the most cost-effective testing approach that provides adequate confidence in product performance.

Frequently Asked Questions

How long does custom cable assembly development typically take?

Development timelines vary quite a bit based on complexity and testing requirements, but you can typically expect 2-8 weeks for standard assemblies. More complex designs requiring extensive validation or custom tooling may require 12-16 weeks, so it's best to plan accordingly and discuss timelines upfront with your manufacturer.

What minimum order quantities should I expect for custom assemblies?

Minimum orders depend on complexity and customization level, but typically range from 25-100 pieces for simple assemblies. Highly specialized or molded assemblies may require higher minimums (sometimes 500-1000 pieces) to justify tooling costs, though many manufacturers are willing to work with smaller quantities for prototyping.

Can existing cable assemblies be modified or upgraded?

Many existing assemblies can be successfully modified by changing connectors, adding shielding, or updating wire specifications to meet new requirements. However, extensive modifications may require a complete redesign to ensure compatibility and performance, so it's worth discussing options with your manufacturer early in the process.

What documentation is provided with custom assemblies?

Standard documentation typically includes assembly drawings, test reports, and material certificates to verify compliance with your specifications. Additional documentation, such as quality manuals, validation reports, or detailed traceability records, may be required for medical, aerospace, or other regulated applications.

How do I ensure my custom assembly meets industry standards?

Working with certified manufacturers familiar with relevant standards is essential for compliance success. They can guide material selection, testing requirements, and documentation needs specific to your industry, potentially saving you significant time and preventing costly compliance issues down the road.

Final Thoughts

Creating successful custom cable assembly projects really comes down to understanding that every detail matters, from initial requirements analysis through final quality control measures. The best results happen when you partner with experienced cable assembly manufacturers who take the time to understand your specific needs and can guide you through the various decisions that affect performance, reliability, and cost. Whether you're developing a groundbreaking medical device or improving an existing industrial system, the right manufacturing partner makes all the difference in delivering assemblies that not only meet your specifications but also exceed your expectations for years of reliable service.

Ready to bring your custom cable assembly project to life with a trusted manufacturing partner who understands your unique requirements? Contact us today to discuss your specific needs and discover how we can help transform your cable assembly vision into reality.

Reference:

https://www.iso.org/standard/59752.html