How Global Sourcing Helps You Overcome Component Shortages

Component shortages can disrupt production, delay product launches, and impact profitability. From semiconductors to raw materials, supply chain disruptions have become a persistent challenge for businesses across industries. Global sourcing offers a strategic solution to mitigate these shortages. By diversifying supply chains and tapping into global resources, companies can reduce risks, maintain production, and stay competitive. This article explores how global sourcing helps businesses overcome component shortages, offering practical strategies and insights for various industries.

Key Takeaways

- Global sourcing diversifies supply chains, reducing reliance on single suppliers.

- Access to international markets provides alternative sources for critical components.

- Strategic partnerships with global suppliers enhance supply chain resilience.

- Technology and data analytics improve visibility and forecasting in global sourcing.

- Effective risk management strategies mitigate disruptions in global supply chains.

- Ethical and sustainable sourcing practices align with modern business values.

Understanding Component Shortages

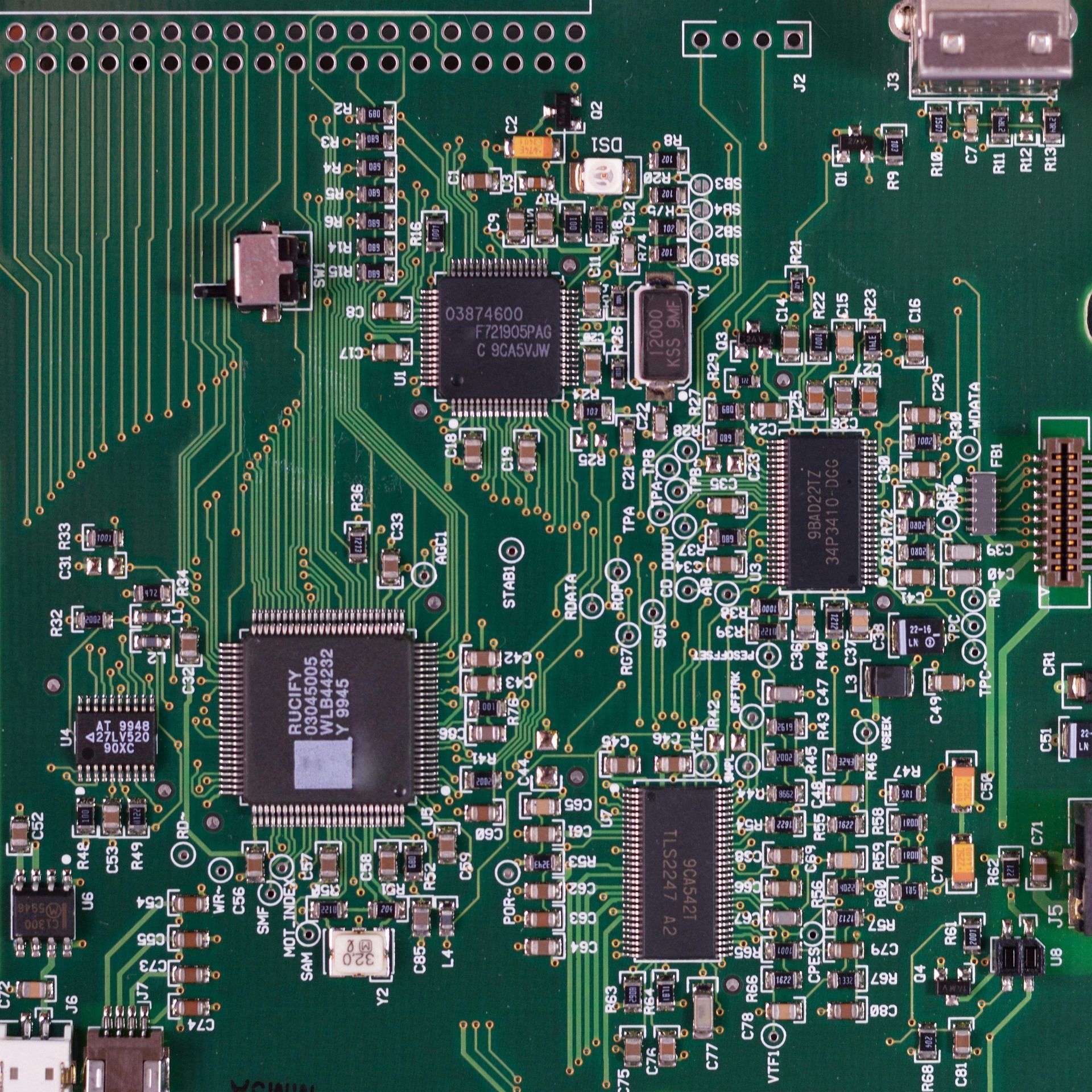

Component shortages occur when the supply of critical materials or parts fails to meet demand. These disruptions can stem from various causes, including natural disasters, geopolitical tensions, trade restrictions, or unexpected demand surges. For example, the global semiconductor shortage that began in 2020 affected industries from automotive to consumer electronics, highlighting the fragility of concentrated supply chains.

Shortages disrupt production schedules, increase costs, and strain customer relationships. When a single supplier or region dominates the supply of a component, any disruption can have cascading effects. Global sourcing addresses this by expanding the pool of suppliers and regions, ensuring businesses have options when local or primary sources falter.

The Role of Global Sourcing in Supply Chain Resilience

Global sourcing involves procuring materials, components, or services from suppliers across different countries. This approach contrasts with localized sourcing, which relies on nearby or single-region suppliers. By casting a wider net, businesses can access diverse markets, reduce dependency on a single source, and buffer against regional disruptions.

For instance, if a natural disaster halts production in one country, global sourcing allows companies to shift to suppliers in unaffected regions. This flexibility is critical in industries like electronics,

medical devices, and manufacturing, where even a single missing component can halt entire production lines. Global sourcing also enables businesses to capitalize on cost advantages, as some regions offer lower production or labor costs.

Benefits of Global Sourcing for Component Shortages

- Diversification: Sourcing from multiple countries reduces the risk of supply chain bottlenecks.

- Access to Innovation: Global suppliers may offer advanced technologies or alternative materials.

- Cost Optimization: Competitive pricing in different markets can lower procurement costs.

- Scalability: Global networks allow businesses to scale sourcing based on demand.

- Risk Mitigation: Spreading suppliers across regions minimizes the impact of localized disruptions.

Strategies for Effective Global Sourcing

To leverage global sourcing effectively, businesses must adopt strategic approaches tailored to their needs. Below are key strategies to overcome component shortages through global sourcing.

1. Build a Diverse Supplier Network

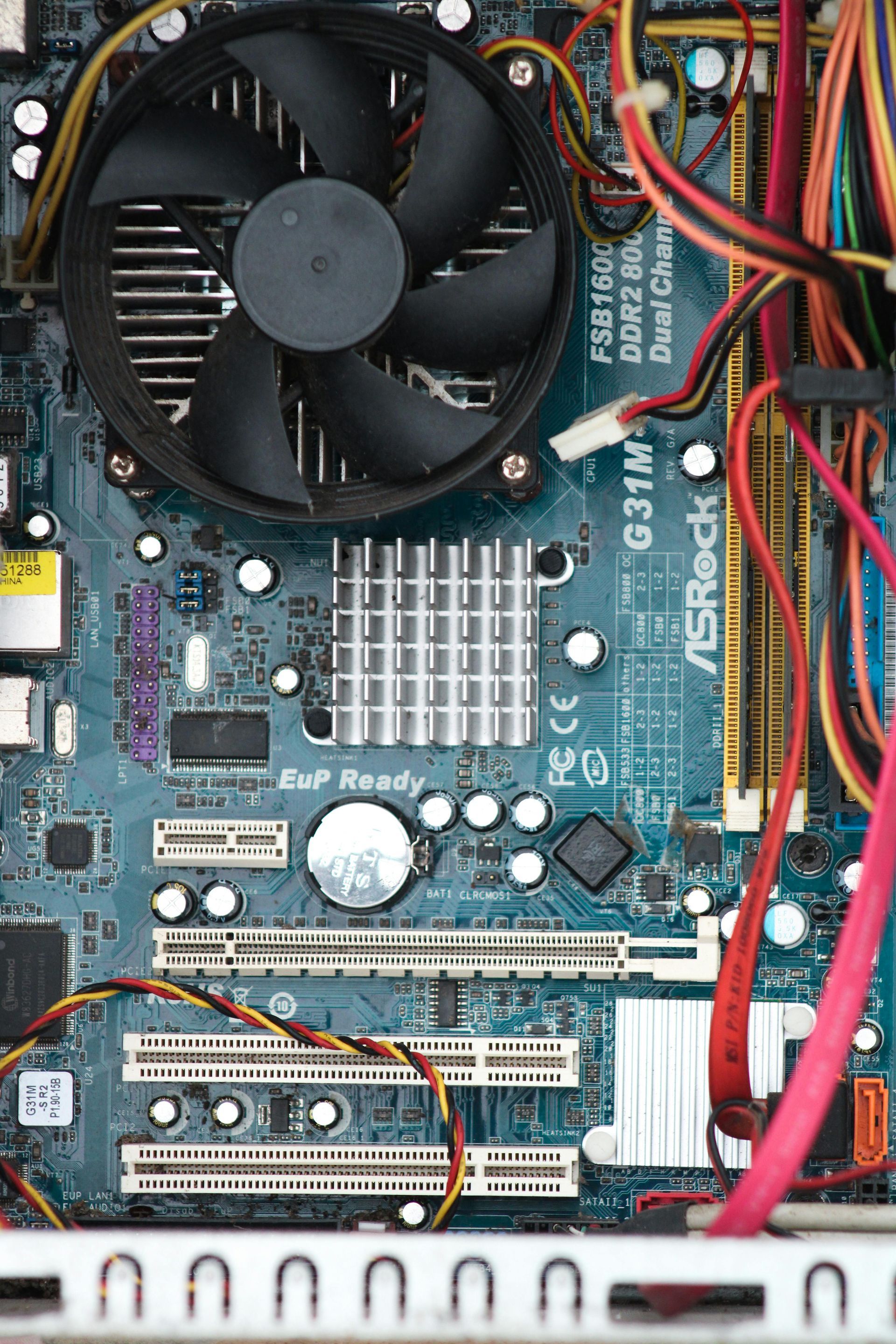

Relying on a single supplier or region increases vulnerability. A diverse supplier network spans multiple countries and continents, ensuring alternative sources for critical components. For example, a manufacturer sourcing semiconductors might partner with suppliers in Asia, Europe, and North America to avoid disruptions from regional issues like trade disputes or natural disasters. Epsems offers services like electronic component distribution to help companies establish reliable supplier networks across the globe.

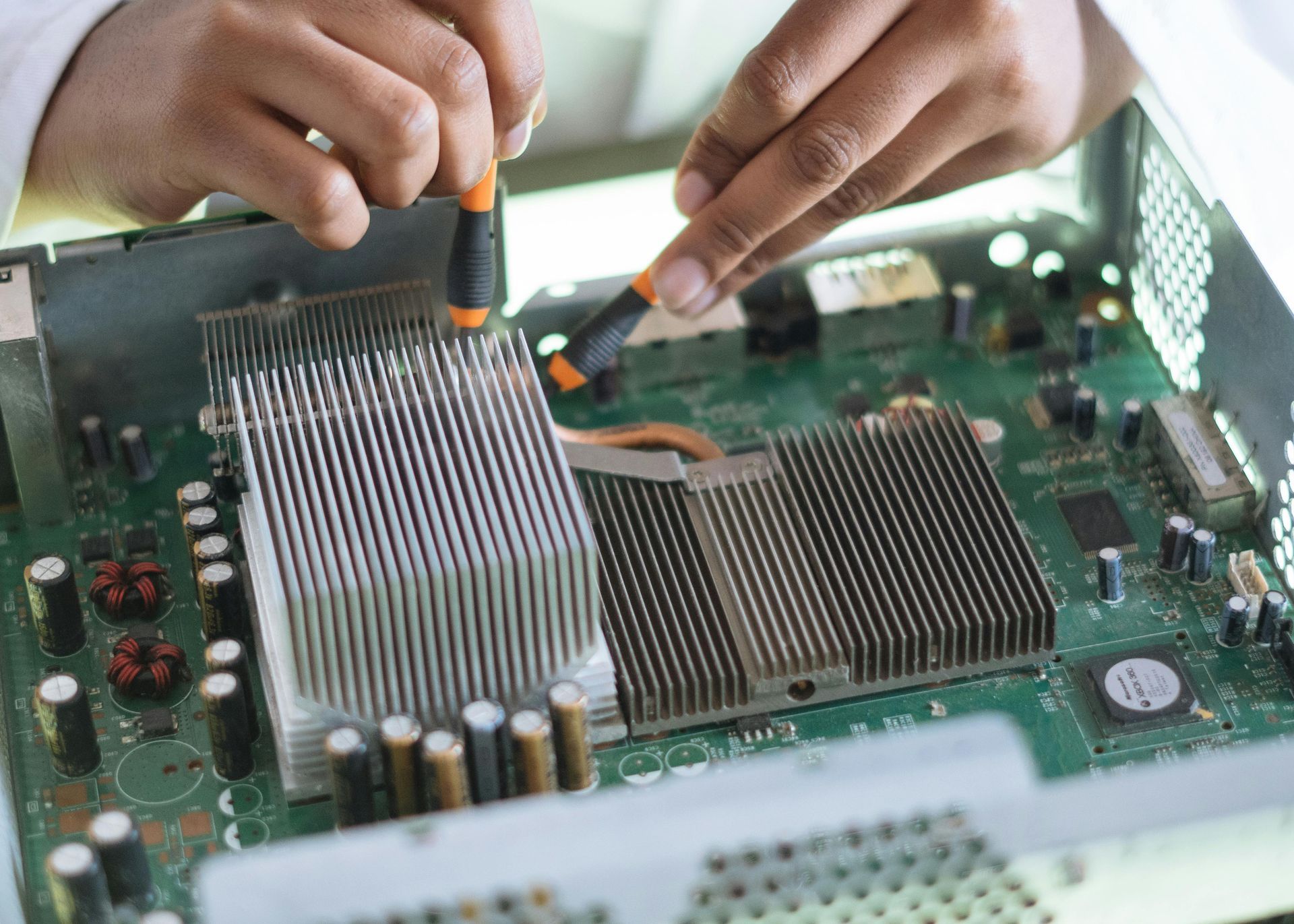

2. Leverage Technology for Supply Chain Visibility

Advanced technologies like supply chain management software, artificial intelligence, and blockchain enhance transparency in global sourcing. These tools provide real-time data on supplier performance, inventory levels, and potential disruptions. For instance, predictive analytics can forecast shortages, allowing businesses to secure components from alternative suppliers proactively.

3. Establish Strategic Partnerships

Strong relationships with global suppliers foster trust and collaboration. Long-term contracts or partnerships encourage suppliers to prioritize your orders during shortages. Regular communication and joint planning also help align production schedules and mitigate risks. If you require end-to-end integration, services like box build assembly can streamline vendor coordination and final product delivery.

4. Conduct Thorough Supplier Assessments

Not all suppliers are equal. Before partnering, assess suppliers for reliability, quality, and capacity. Evaluate their financial stability, production capabilities, and ability to meet demand during crises. Audits and site visits can ensure compliance with quality and ethical standards. This is particularly important in regulated sectors like aerospace and defense, where compliance and traceability are critical.

5. Implement Risk Management Practices

Global sourcing introduces risks like currency fluctuations, regulatory changes, and logistical challenges. Risk management strategies, such as dual-sourcing (using two suppliers for the same component) or maintaining safety stock, can mitigate these issues. Scenario planning also prepares businesses for potential disruptions. Working with companies that support excess inventory resale can also help manage overstock risks while recovering value from unused components.

| Strategy | Benefit | Example Application |

|---|---|---|

| Diverse Supplier Network | Reduces single-source dependency | Sourcing from Asia, Europe, and North America |

| Technology Integration | Improves visibility and forecasting | Using AI for demand prediction |

| Strategic Partnerships | Ensures priority during shortages | Long-term contracts with key suppliers |

| Supplier Assessments | Ensures quality and reliability | Conducting supplier audits |

| Risk Management | Minimizes disruption impact | Maintaining safety stock |

Challenges of Global Sourcing

While global sourcing offers significant benefits, it also presents challenges that businesses must navigate.

Logistical Complexities

Sourcing from multiple countries involves complex logistics, including shipping, customs, and tariffs. Delays in transportation or regulatory hurdles can offset the benefits of diversification. Businesses must invest in robust logistics partners and expertise to streamline operations.

Quality Control

Differences in manufacturing standards across countries can lead to inconsistent quality. Establishing clear quality benchmarks and conducting regular audits help maintain standards. Collaborating with suppliers to align processes can also address this issue. A trusted partner for custom cable assembly can ensure that specialized components meet required standards consistently.

Cultural and Communication Barriers

Working with international suppliers requires navigating cultural differences and language barriers. Miscommunication can lead to delays or errors. Investing in cross-cultural training and clear communication channels can bridge these gaps.

Ethical and Sustainability Concerns

Global sourcing must align with ethical and sustainable practices. Consumers and regulators increasingly demand transparency in supply chains, particularly regarding labor conditions and environmental impact. Partnering with suppliers who adhere to ethical standards is essential.

Frequently Asked Questions

What is global sourcing, and how does it differ from local sourcing?

Global sourcing involves procuring goods or services from international markets, while local sourcing relies on suppliers within a single region or country. Global sourcing offers greater diversification and access to global resources but involves more complex logistics.

How can global sourcing help during component shortages?

Global sourcing provides access to alternative suppliers in different regions, reducing reliance on a single source. This diversification ensures businesses can secure components even when one supplier or region faces disruptions.

What are the risks of global sourcing?

Risks include logistical delays, quality inconsistencies, currency fluctuations, and regulatory challenges. Businesses can mitigate these through careful supplier selection, robust logistics, and risk management strategies.

How can technology improve global sourcing?

Technologies like AI, blockchain, and supply chain software enhance visibility, predict shortages, and streamline communication with suppliers. These tools help businesses make informed sourcing decisions.

Is global sourcing sustainable?

Global sourcing can be sustainable if businesses partner with suppliers who adhere to ethical and environmental standards. Transparency and regular audits ensure alignment with sustainability goals.

Final Thoughts

Component shortages are a reality in today's complex supply chains, but global sourcing offers a powerful solution. By diversifying supplier networks, leveraging technology, and building strategic partnerships, businesses can navigate disruptions and maintain production. While challenges like logistics and quality control exist, careful planning and risk management can address them effectively. As markets continue to evolve, global sourcing will remain a critical strategy for businesses seeking resilience and competitiveness. By adopting these practices, companies can turn supply chain challenges into opportunities for growth and innovation.

Ready to strengthen your supply chain? Contact our team today to learn how EPS can support your global sourcing strategy.