Box Build Assembly and Systems Integration for Legacy Electronics

If you're dealing with aging electronic systems, you know how frustrating it can be when components break down and replacements are nowhere to be found. Box build assembly paired with systems integration offers a practical electronic sourcing solution. Instead of scrapping your entire system or paying premium prices for rare parts, this approach lets you keep your specialized equipment running while making smart upgrades along the way.

Key Takeaways

- Box build assembly gives you complete electronic system solutions, not just individual parts

- Systems integration services help you connect old and new electronic components smoothly

- Working with the right distributors gets you access to hard-to-find components you can trust

- Updating legacy systems takes planning, but you can keep everything working properly

- Professional assembly services help you avoid the headaches of component shortages and system breakdowns

- Finding the right partners makes the whole process much easier

Understanding Legacy Electronics Challenges

Many businesses rely on electronic systems that have been running for years or even decades. These workhorses keep factories humming, medical equipment functioning, and critical infrastructure operating. The problem comes when parts start failing and you discover the manufacturer stopped making replacements long ago.

It gets more complicated than just finding parts. Older systems often use special interfaces, custom software, and unique communication methods that newer components don't understand. This creates a puzzle where all the pieces need to fit together just right.

The economics of legacy system maintenance can become overwhelming quickly. As components become rarer, prices increase dramatically. What used to cost a few dollars might now cost hundreds or even thousands. Meanwhile, system downtime costs continue mounting, sometimes reaching thousands of dollars per hour for critical applications.

When you're facing obsolete systems, you have a few paths to consider:

- Replace everything, which costs a lot and might shut down operations for a while

- Keep patching with expensive and increasingly unreliable old parts

- Smart upgrades using box build assembly and integration services

- Mix and match keeping what works while adding modern improvements

The choice depends on factors like system criticality, available budget, operational requirements, and long-term business plans. Many organizations find that a phased approach works best, allowing them to spread costs over time while minimizing operational disruption.

Box Build Assembly Solutions

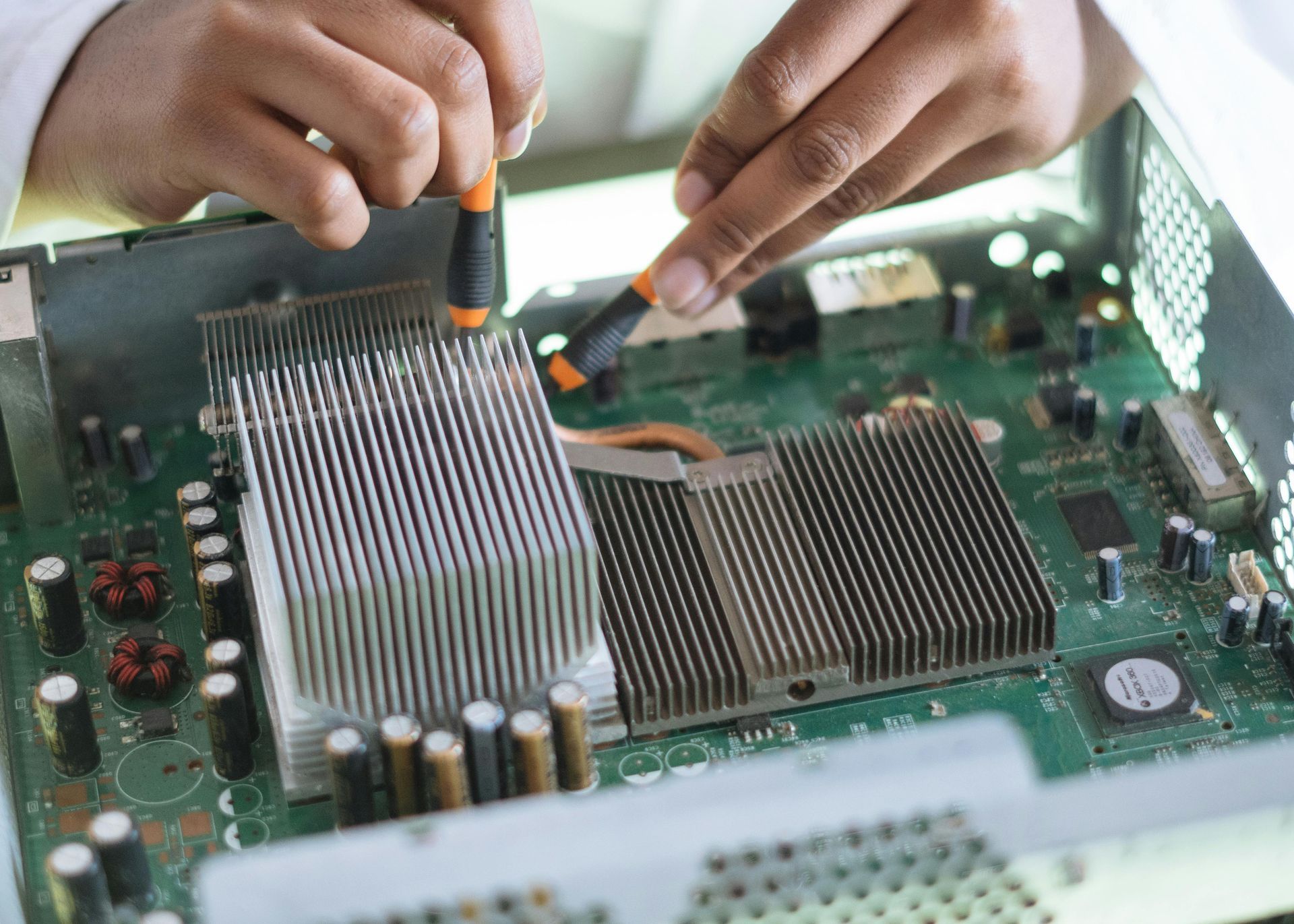

Box build assembly means getting a complete working system, not just a bag of parts. Think of it as having someone build your entire electronic system from scratch, test it thoroughly, and hand you something that's ready to plug in and use.

The process starts by taking a close look at what you currently have and what you actually need. Engineers examine how everything works together, figure out which parts are most important, and create a plan that keeps your system running as well as (or better than) before.

Modern box build services offer comprehensive solutions that include design engineering, component sourcing, manufacturing, testing, and ongoing support. This full-service approach helps ensure that your final system not only works but continues working reliably for years to come.

Here's what good box build services include:

- Finding and checking components from suppliers you can count on, including authentication services and quality verification

- Custom circuit board design made specifically for what you need, incorporating modern manufacturing techniques

- Putting everything together in proper enclosures that meet safety standards and environmental requirements

- Testing everything thoroughly to make sure it all works correctly under actual operating conditions

- Giving you proper paperwork so you know exactly what you're getting, including traceability records

Quality checks happen at every step to catch problems early. This means inspecting parts when they arrive, testing things as they're built, and making sure the final system works perfectly before it leaves the shop. Advanced testing might include environmental stress screening, burn-in procedures, and accelerated life testing to identify potential reliability issues.

Professional facilities maintain controlled environments with proper electrostatic discharge protection, clean air systems, and temperature control. These conditions help ensure that sensitive electronic components aren't damaged during assembly.

Systems Integration for Obsolete Components

Systems integration is about making old and new technology work together smoothly. It's like being a translator between different generations of electronics that speak different languages.

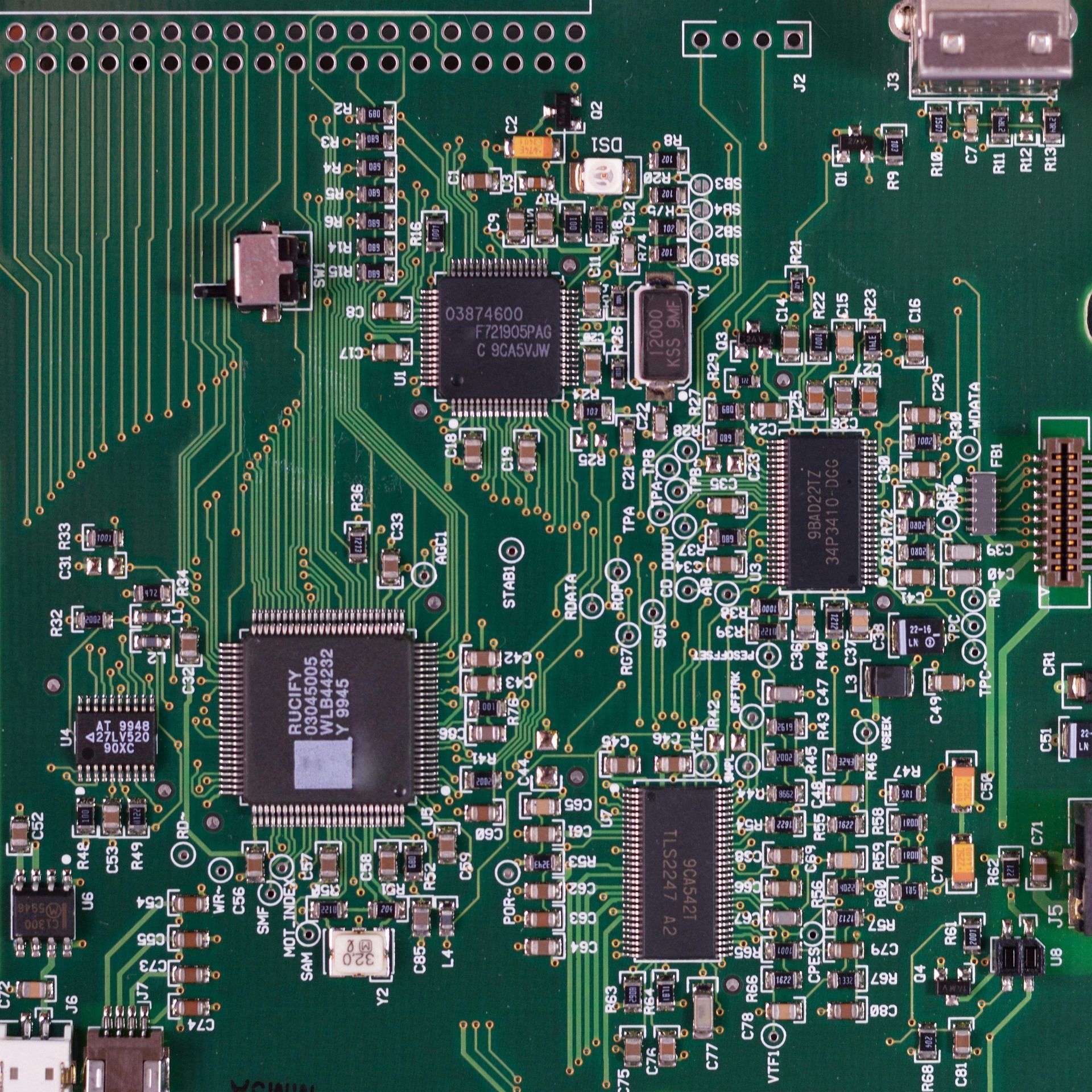

The first step is understanding exactly how your current system works. Engineers map out all the connections, figure out how different parts communicate, and identify where modern components can fit in without breaking anything.

Legacy systems often present unique integration challenges that require creative solutions. Signal levels might differ between old and new components, timing requirements may have changed, or communication protocols might be incompatible. Experienced integration teams know how to work around these issues using interface circuits, signal conditioning, and protocol conversion techniques.

Here's how the integration process typically works:

Understanding Your Current System

- Documenting how everything connects and works together, including creating detailed schematics and interface specifications

- Finding all the communication paths and protocols throughout the system

- Checking what performance levels you need to maintain, including speed, accuracy, and reliability requirements

- Making sure any changes meet safety and regulatory requirements specific to your industry

Finding the Right Replacement Parts

- Locating modern components that can do the same job as obsolete electronic components while maintaining performance

- Making sure new parts can talk to your existing equipment through proper interface design

- Working with trusted obsolete electronic components distributor networks to source authentic components

- Testing everything to make sure it's authentic and works properly under your specific conditions

Planning and Making the Changes

- Creating step-by-step plans with realistic timelines that account for testing and validation

- Building custom interfaces when old and new parts need to communicate

- Writing or modifying software to support new components while maintaining compatibility

- Running thorough tests to make sure everything works together under all operating conditions

Integration projects often uncover opportunities for improvement beyond simple component replacement. Modern components might offer enhanced features, better reliability, or improved performance that can benefit your overall system operation.

Sourcing Hard-to-Find Components

Finding obsolete electronic components takes know-how and good connections. The best distributors keep large inventories of older parts and can verify that what you're getting is genuine and in good condition.

The component sourcing landscape has changed dramatically over the years. Authorized distribution channels typically focus on current products, leaving a gap for older components. This has created a specialized market of brokers, surplus dealers, and aftermarket suppliers who focus specifically on hard-to-find components.

Smart sourcing uses several approaches to make sure you can get what you need. You might work with authorized distributors, find manufacturer overstock, or use specialized brokers. Each option has its place, but you need to be careful about quality and authenticity.

| Component Source Type | What's Good About It | What to Watch Out For |

|---|---|---|

| Authorized Distributors | You know it's real, full documentation | Not much old stuff, costs more |

| Manufacturer Surplus | Original parts, good prices | Availability changes, might need large orders |

| Specialized Brokers | Great connections, can find rare parts | Need to verify authenticity carefully |

| Aftermarket Suppliers | Usually cheaper, easier to find | Quality varies, limited guarantees |

Good suppliers have solid processes for checking that parts are authentic. They inspect components visually, test them electrically, and review all the documentation. This helps ensure you're getting parts that will actually work and last.

Counterfeit components represent a significant risk in the obsolete electronics market. Professional suppliers invest heavily in authentication equipment and training to identify fake parts. This includes visual inspection under magnification, electrical parameter testing, package analysis, and documentation verification.

Lead times for obsolete components can vary dramatically. Some common parts might be available immediately, while rare or specialized components could take weeks or months to locate. Building buffer inventory for critical components helps avoid extended downtime when failures occur.

Implementation Strategies and Best Practices

Planning a legacy electronics update takes some thought, but it doesn't have to be overwhelming. The key is balancing what you need right now with what makes sense for the long term.

Start by figuring out how critical each system is. Your most important equipment might need backup plans and careful timing, while less critical systems can handle more aggressive updates.

Successful implementation often requires coordination across multiple departments. Engineering teams need to understand technical requirements, procurement groups must source components effectively, and operations staff require training on new systems.

Managing Risks

- Having solid backup plans for your most important systems, including spare components and alternative procedures

- Rolling out changes in phases so you can test as you go and minimize impact

- Planning for delays in getting parts or unexpected problems during integration

- Knowing how to undo changes if something goes wrong, including maintaining rollback capabilities

Keeping Quality High

- Testing individual parts and complete systems thoroughly using both automated and manual procedures

- Making sure everything works under real operating conditions, including environmental stress testing

- Running longer tests to check reliability over time, including accelerated aging

- Verifying that everything meets the standards you need for your specific industry

Choosing the Right Partners

- Finding companies with experience in similar projects in your industry

- Making sure they have good relationships with reliable obsolete electronics supplier networks

- Checking their quality systems and certifications, including ISO standards

- Confirming they understand your type of equipment and technology

Good communication and documentation throughout the project help everything go smoothly and give you valuable information for future maintenance. Change management becomes particularly important when updating legacy systems, as operators may have years of experience with existing equipment.

Future-Proofing Legacy Systems

Smart planning for legacy electronics goes beyond just fixing what's broken today. It makes sense to think ahead about what might become obsolete next and how technology will continue changing.

The best approach often involves selective updates that keep the critical old stuff working while bringing in modern components where it makes sense. This helps you control costs while making your systems more reliable and easier to maintain.

Good future-proofing usually includes:

- Technology planning that anticipates when components might become obsolete based on manufacturer roadmaps

- Smart inventory management for critical parts that might be hard to get later

- Building relationships with multiple suppliers so you have options when primary sources become unavailable

- Keeping good records so future maintenance and upgrades go smoothly

- Training your team so they can handle legacy system maintenance

Regular check-ups help you spot potential obsolescence problems before they become emergencies. This lets you plan updates during scheduled downtime instead of scrambling when something breaks unexpectedly.

Standardization efforts can also help with future-proofing. Where possible, migrating toward more common interface standards and widely available components reduces the risk of future obsolescence issues.

Frequently Asked Questions

How long does a typical box build assembly project take for legacy electronics?

Most standard projects take about 8-16 weeks, depending on how complex your system is and how easy it is to find parts. More complicated systems with really hard-to-find components might need extra time for sourcing and testing.

What quality checks ensure my assembled system will work reliably?

Professional assembly services test everything multiple times, including checking each component, testing during assembly, and validating the complete system. They also do environmental testing and run systems for extended periods to make sure everything works properly long-term.

What happens if you can't find obsolete components anywhere?

Experienced teams can develop workarounds like redesigning components, finding modern equivalents, or replacing entire subsections. The goal is always to keep your system working while using parts you can actually get.

What kind of documentation do I get with box build assembly services?

You'll typically get complete documentation, including assembly drawings, parts lists, test procedures, and certification records. This paperwork helps with future maintenance and meeting any regulatory requirements.

How do you make sure old and new components work together?

This involves careful analysis of how things connect, electrical testing, and real-world validation under actual operating conditions. Sometimes custom interface circuits or software modifications are needed to make everything communicate properly.

Final Thoughts

Box build assembly and systems integration give you practical ways to handle obsolete electronics problems without breaking the bank. Working with experienced teams who understand both older systems and modern components helps you keep critical equipment running while making smart improvements. Good planning and professional help ensure you get results that work for today while setting you up for whatever comes next.

Planning a legacy system upgrade? Contact us for a consultation on your box build assembly and integration requirements.

Reference:

https://www.researchgate.net/publication/355616003_Electronic_Components_Authentication_Methods_Based_on_Decapsulation_and_Chip_Photo_Analysis